Bending Machines

From precision press brakes to fully automated bending cells, TRUMPF bending machines deliver the power, accuracy, and flexibility modern fabricators need. Whether you’re bending small batches, high-volume parts, or large panels, Maintecx helps you configure the right TRUMPF system for your production goals.

Built on decades of TRUMPF innovation, each machine combines ergonomic design, intelligent control, and automation-ready performance so your team can bend faster, safer, and with greater consistency.

Explore Our TRUMPF Bending Machines

New affordable CNC press brake offering precise bending at a low cost of entry for fabricators adding capacity or modernizing manual setups.

Reliable TRUMPF quality in an entry-level machine, balancing affordability with consistent performance and minimal setup time.

Combines efficiency and accuracy for a wide range of sheet metal jobs, with intelligent angle measurement and fast cycle times.

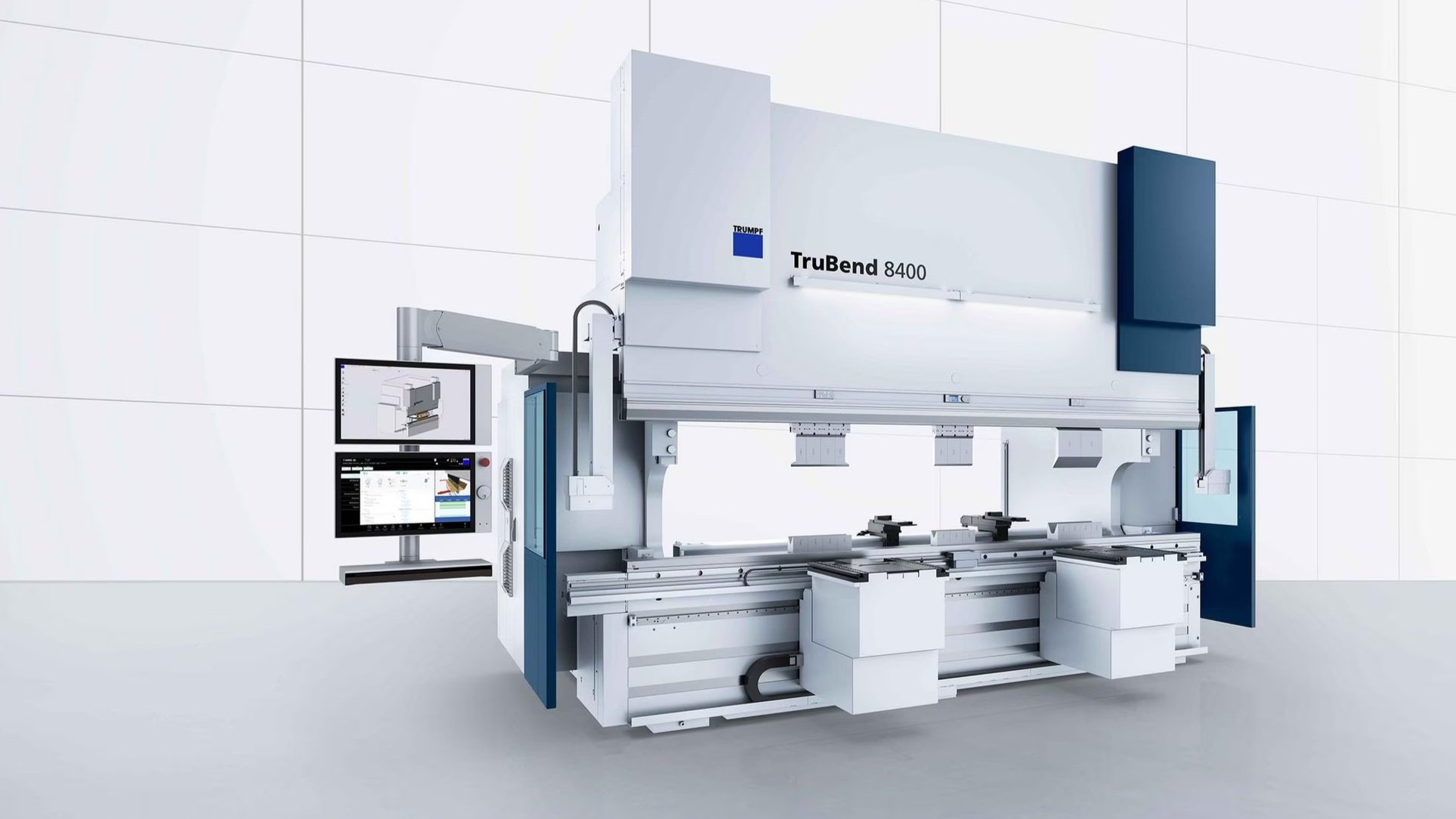

TRUMPF’s most popular press brake series, engineered for high productivity from setup to bending. Smart automation, precision sensors, and intuitive controls keep operators efficient across all shifts.

A high-speed, ergonomic press brake designed for small and medium-sized parts for shops focused on fast changeovers and operator comfort.

Built for bending large-format components with exceptional speed and precision. Extended press beam and stroke options make it ideal for oversized parts.

TRUMPF Automated Bending Solutions

A fully automated bending cell that handles a wide range of part geometries with consistent accuracy. Built for continuous, flexible operation with minimal supervision.

Delivers all the benefits of automation in a compact footprint. Intuitive programming and quick gripper changes make it ideal for mixed-part production.

Compact, high-speed automation for small parts. Perfect for high-mix, low-volume jobs requiring short cycle times and repeatable precision.

TRUMPF Panel Bending Systems

Offers the widest part range in its class, with TRUMPF’s advanced panel-bending technology for complex geometries and aesthetic surface parts.

Delivers top productivity with 60% greater box height and faster cycle times for deep parts and flexible batch sizes.

A fully automatic panel-bending system featuring rotary part manipulation and integrated loading/unloading for maximum productivity.

Why Fabricators Choose TRUMPF Bending Machines from Maintecx

TRUMPF bending machines combine precision engineering with operator-focused design to make every bend faster, smarter, and more consistent.

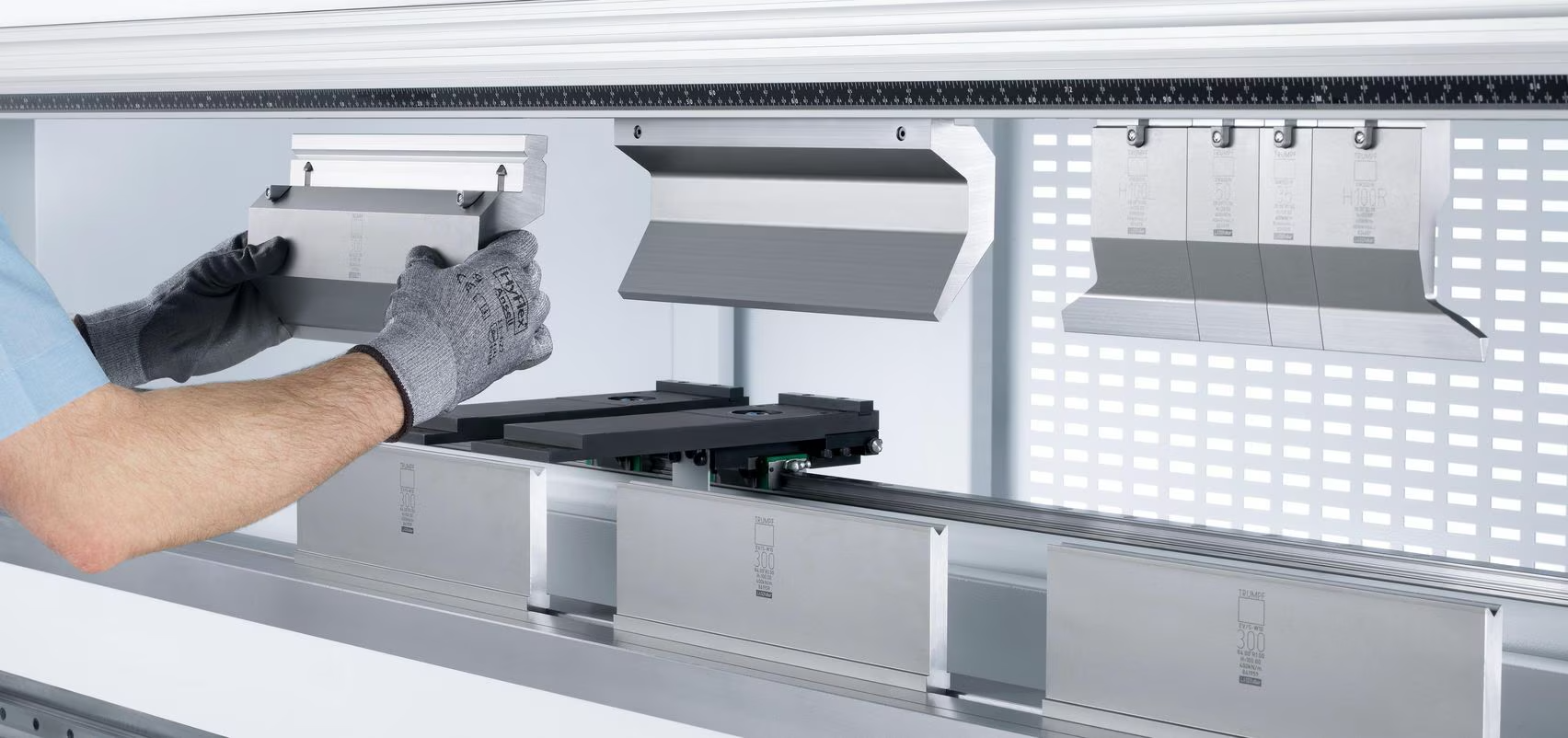

Smarter setups: QuickClamp systems, intelligent tool positioning, and automatic angle measurement reduce changeover time.

Operator-friendly design: Adjustable control panels, foot pedals, and ergonomics support safer, faster work.

Automation-ready: From manual to fully automated cells, TRUMPF systems scale with your production needs.

Connected production: Seamlessly integrates with TRUMPF TruTops software and Smart Factory solutions for end-to-end process visibility.

Local expertise: Maintecx helps you plan layouts, automation paths, and machine configurations tailored to your workflow.

Choosing the Right TRUMPF Punch For Your Shop

Whether you’re forming small brackets, large panels, or running high-mix batches, there’s a TRUMPF solution designed for your shop’s pace and precision. Here’s a quick guide to help narrow it down:

Growing shops: The TruBend 2100 and Series 1000 provide reliable, entry-level performance that scales with your workload.

Versatile job shops: The TruBend Series 3000 delivers balanced speed, accuracy, and flexibility across a wide range of materials and thicknesses.

High-volume production: The TruBend Series 5000 and 8000 maximize throughput with automation-ready features and rapid tool setup.

Small-part specialists: The TruBend Series 7000 and Cell 7000 combine compact footprints with high-speed bending and ergonomic operation.

Complex or large panels: The TruBend Center 7030 and 7020 use panel-bending automation for fast, consistent results for deep boxes or aesthetic parts.

Need more tailored guidance? Talk to a Maintecx expert

View Metal Bending In Action

FAQs About TRUMPF Bending Machines

-

A press brake bends material along a single line at a time using a punch and die, while a panel bender automatically manipulates the sheet to create multiple bends for box- or tray-shaped parts.

-

Yes. TRUMPF offers modular automation options, such as BendMaster and ToolMaster, that can be added as your production grows.

-

They handle a wide range of materials, including mild steel, stainless steel, aluminum, and coated sheets with programmable bending parameters for each.

-

Maintecx’s engineering team will assess your job mix, batch sizes, and throughput goals to recommend the best-fit system, whether a standalone press brake or a fully automated cell.

Learn More About Bending

-

How Smart Bending Improves Accuracy, Speed & Labor Efficiency

-

TRUMPF Flex Cell: TRUMPF’s Fastest Mobile Bending Cell

Upgrade Your Bending Operation

We’ll walk you through the differences between models and help you configure the best bending machine setup for your shop and applications. Contact us to request a quote or explore your options with a Maintecx Rep.