Slat Cleaners 101: How to Get Cleaner Laser Cuts & Longer Slat Life

Dirty slats ruin cut quality and reflect heat. Learn how a slat cleaner like the TRUMPF TSC 100 or TSC 200 extends slat life and ensures cleaner laser cuts.

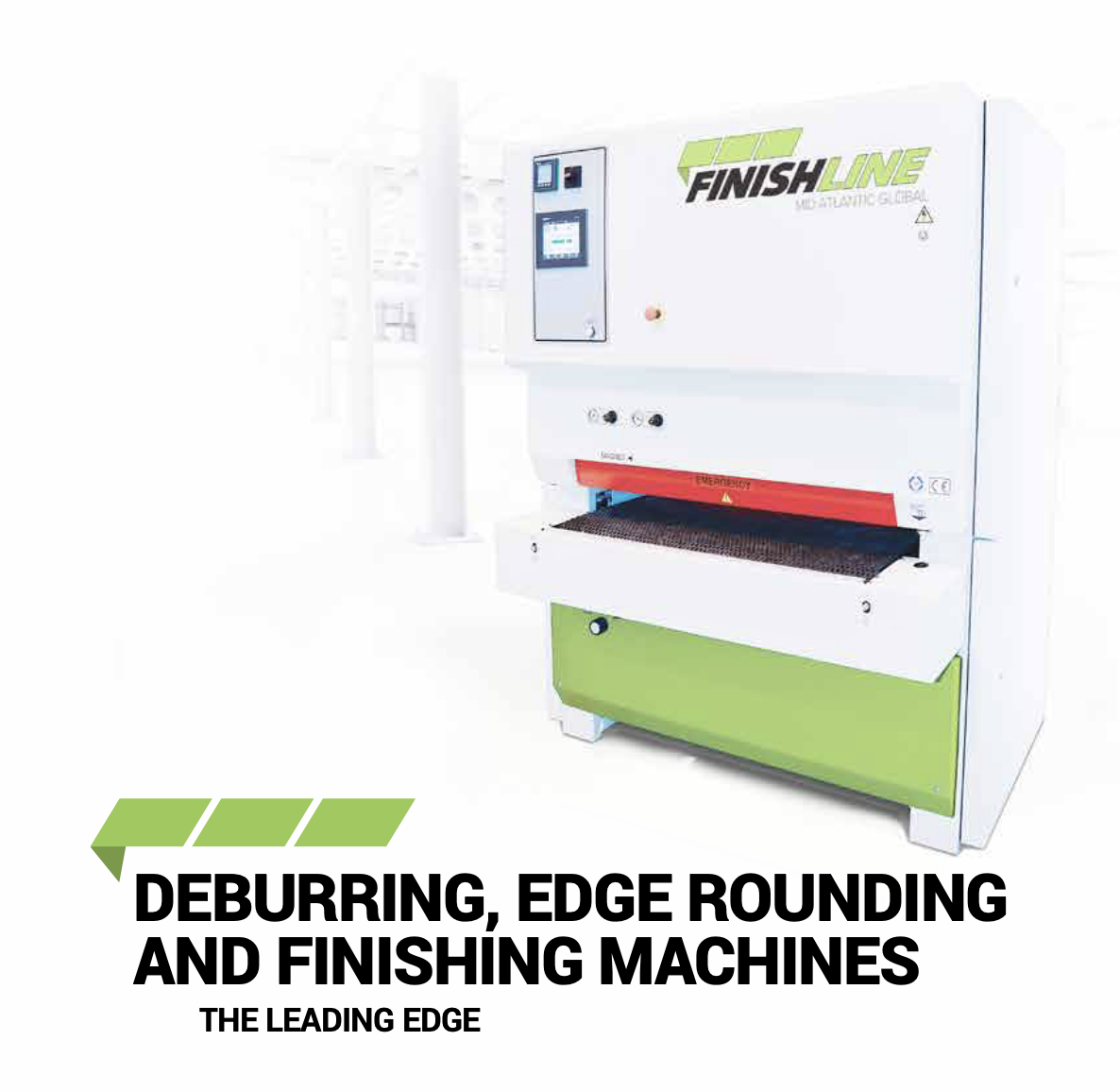

Speed, Safety, & Spec: Automate Deburring with FINISHLINE

Manual deburring is slow, inconsistent, and dangerous. See how FINISHLINE automated deburring boosts throughput, protects staff, and delivers repeatable quality.

On-Site Nitrogen Generation vs. Liquid Supply: The True Cost of Laser Cutting Gas

Compare the true cost of nitrogen gas for laser cutting by reviewing liquid supply vs. on-site generation for ROI, reliability, and cut quality.

Smarter Tube Bending Starts Here: What Makes transfluid Stand Out

transfluid CNC tube benders simplify programming, reduce scrap, and support complex geometries with automation and TRUMPF integration.

How To Reduce Manufacturing Costs With TRUMPF

Discover how TRUMPF machines and automation reduce manufacturing costs. Learn how different tools improve efficiency, reduce waste, and boost profitability.

Your ERP Isn’t the Problem. Your Factory Layout Is.

Think your ERP is slowing you down? It’s not the software. It’s your floor. Learn how TRUMPF Smart Factory layouts and automation unlock real lean efficiency.

Why Most Fabrication Job Shops Are 5 Years Behind & Don’t Know It

Still running parts the old way? Discover the technology, layout, and workflow upgrades job shops need today, and how Maintecx + TRUMPF can help you leap ahead.

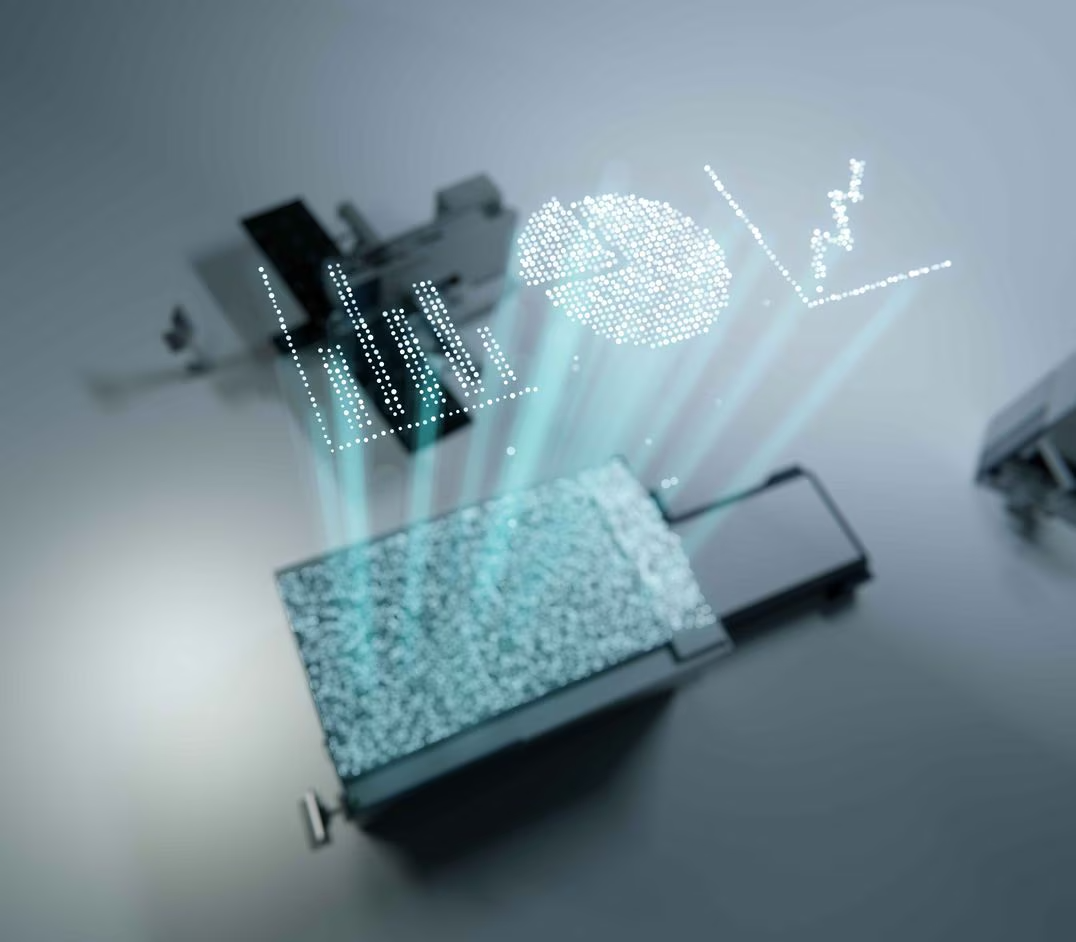

Why Fabrication Shops Should Act More Like Data Centers

Fabrication shops should start acting more like data centers by embracing data-driven operations, connectivity, and automation.

When’s the Last Time You Had a Manufacturing Process Audit?

Is your shop running at full potential? Discover why a manufacturing process audit can reveal hidden inefficiencies and how Maintecx’s experts can help.

The Big Beautiful Bill Just Flipped the Script for U.S. Manufacturing

See how the Big Beautiful Bill helps U.S. manufacturers: equipment expensing, R&D deductions, job creation, and more. Learn how Maintecx can help you qualify.

Unlocking Operator Potential: How Expert Training & TRUMPF Applications Drive Performance

Maintecx offers expert training and applications support that help your team master the tools, reduce downtime, and drive continuous performance improvements.

How Smart Bending Improves Accuracy, Speed & Labor Efficiency

Learn how smart bending technology improves accuracy, speed, and labor efficiency and how TRUMPF’s TruBend Series 1000 makes it accessible for small shops.

Welcoming a New Applications Engineer to The Maintecx Team

Meet the newest member of the Maintecx team, Jon Lysne. As our new Applications Engineer he’s here to bring more efficiency to our clients’ shop floors.

Common Bottlenecks in Metal Fabrication & The Machines That Can Eliminate Them

Every fabrication shop faces bottlenecks, but they don’t have to be permanent. We’ll walk through some of the most common bottlenecks in metal fabrication and show how Maintecx can help eliminate them with automation-ready machines from TRUMPF.

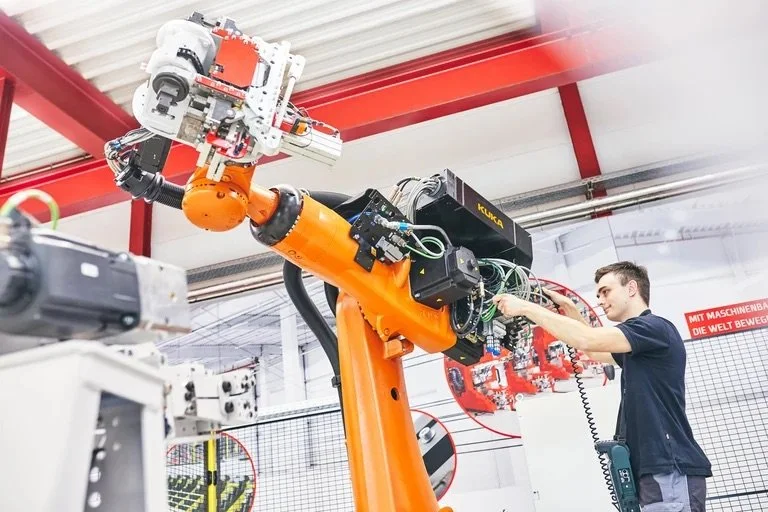

The Future of Skilled Labor in Fabrication: How Automation Can Fill the Gap

This labor gap is already affecting fabrication shops. With fewer hands on deck, manufacturers are struggling to meet demand, leading to production bottlenecks, longer lead times, and increased costs. So, how do fabricators keep up?

Welcoming Two New Sales Engineers to the Maintecx Team!

Meet the newest members of the Maintecx team. Mitch and Dean both have extensive knowledge in manufacturing technology and we are excited for them to start helping our clients in innovative ways.

The Rise of AI in Manufacturing: A Strategic Guide for Industry 4.0

This guide explores how AI is redefining manufacturing, the rise of smart factories, and what manufacturers need to know to navigate this transformation strategically.

How to Optimize Your Fabrication Workflow with TRUMPF Software

We’ll explore the challenges of traditional workflows, strategies to improve them, and the specific ways TRUMPF software can transform your operations.

Construction Equipment Market Outlook 2025: Navigating the Shift from Plateau to Growth

Explore what’s coming for the industry in 2025, based on the latest economic forecasts, and how businesses can prepare to stay ahead.