TruBend Center 7030

High-Speed, High-Flexibility Panel Bending

The TRUMPF TruBend Center 7030 is built for high-speed panel bending with maximum flexibility and minimal manual input. Whether you're running small batches or full-scale production, this machine delivers unmatched efficiency through fully automated bending, tool changing, and part handling.

Key Features

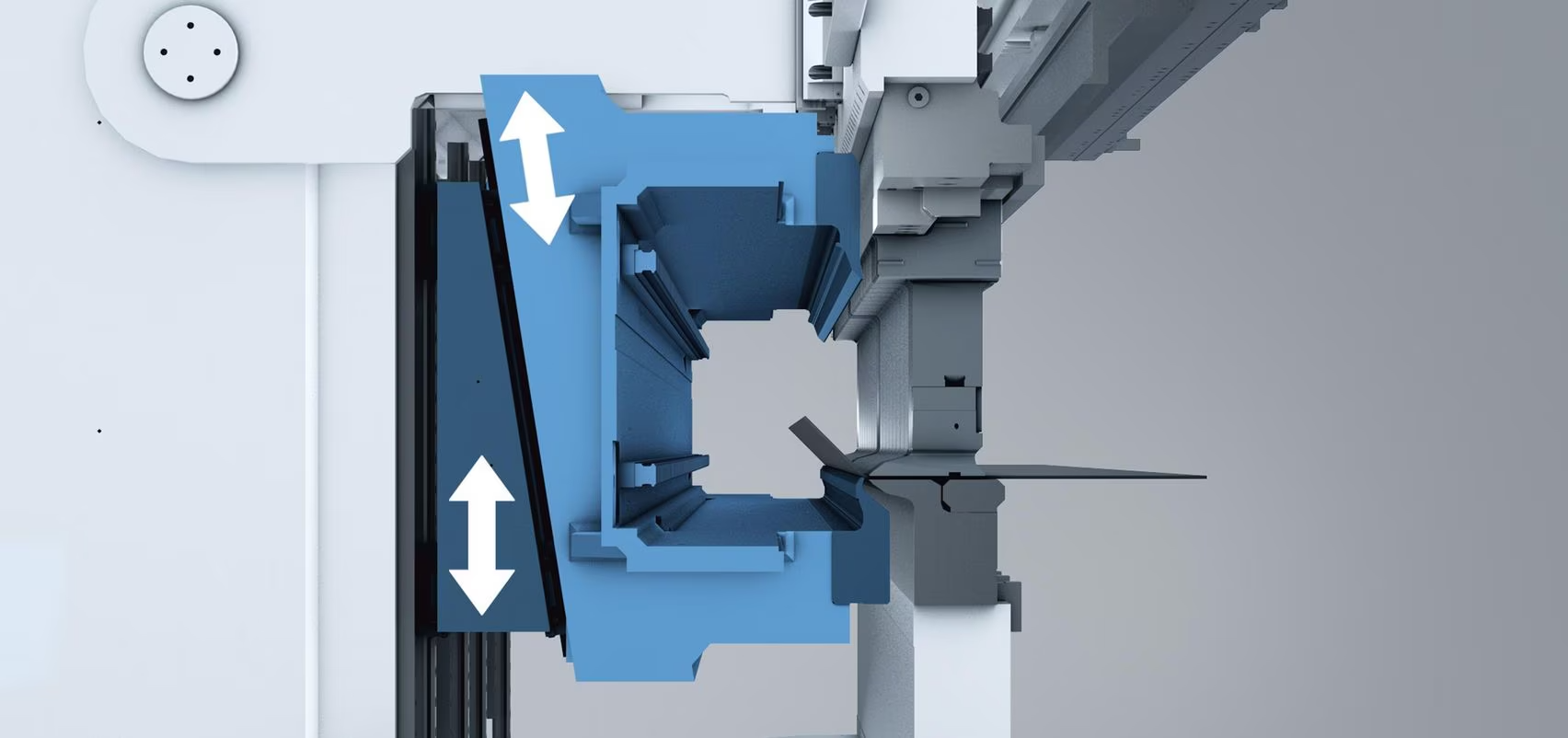

Fully Automated Panel Bending: Supports high-speed, bi-directional bending for complex geometries, including short flanges and radii.

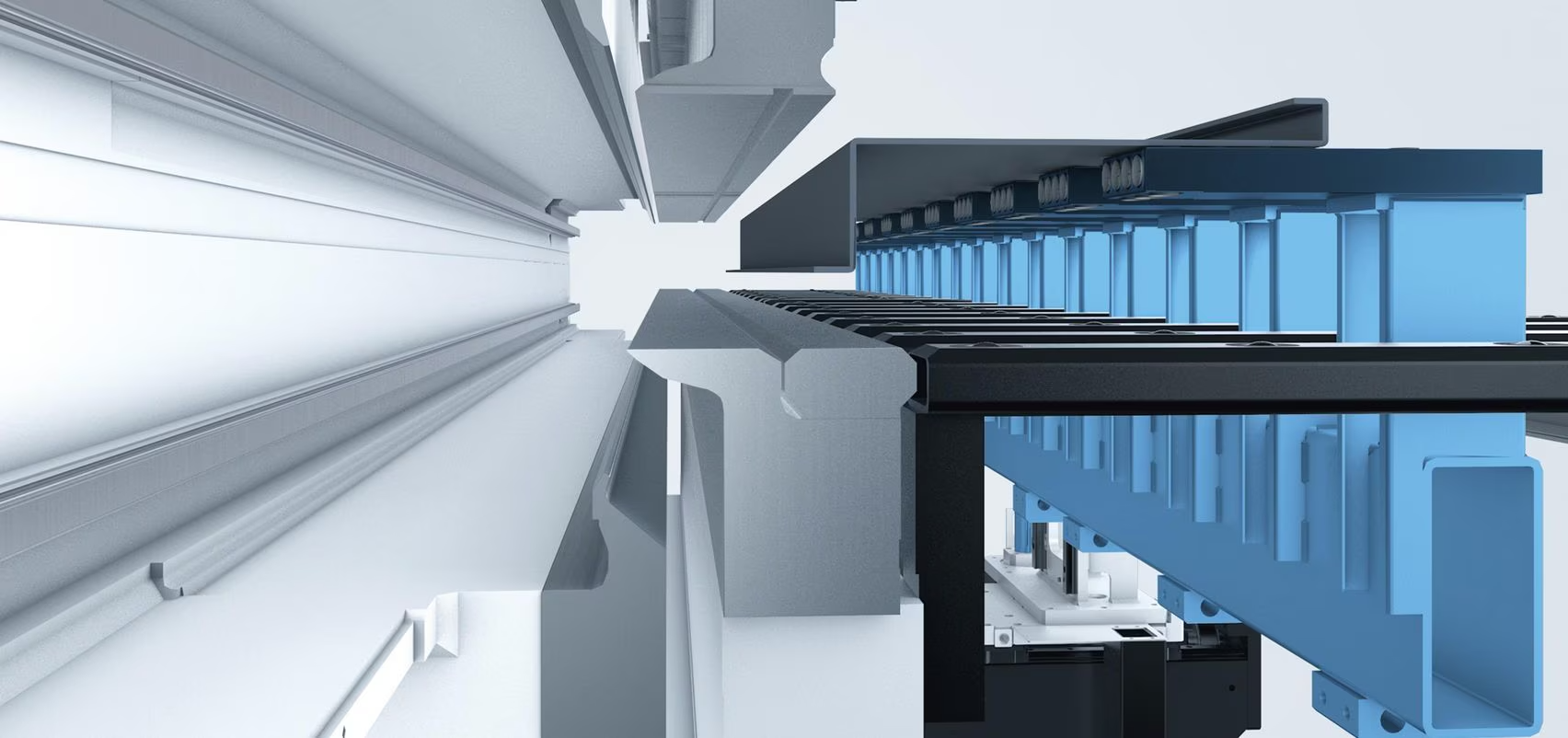

Automated Loading & Unloading: Stack blanks on the intake side and let the system handle the rest. A suction device picks and verifies each sheet before transferring it via a brush table and alignment system into the bending zone, while the machine continues operating. A loading carriage simultaneously removes completed parts to a conveyor.

ToolMaster for Fast Tool Changes: Change tools up to 70% faster with TRUMPF’s ToolMaster, which now supports simultaneous swapping of multiple small tools. This feature slashes setup time and maximizes machine uptime.

TecZone Fold Software: Offline programming made easy. Operators can program parts in just a few clicks with full 3D simulations and built-in collision detection, all completed in seconds.

Uninterrupted Productivity: The machine performs loading, unloading, tool changes, and bending all in one continuous, integrated cycle, with no need for manual intervention.

Applications

The TruBend Center 7030 is perfect for:

HVAC panels, electrical cabinets, and control boxes

Architectural panels and sheet metal cladding

Appliance components and industrial enclosures

Furniture, storage, and retail fixtures

TruBend Center 7030 Technical Data

Maximum Bending Length

123 in

Minimum Bending Length

8 in

Maximum Box Height

8.66 in

Maximum Sheet Size

120 in x 60 in

Maximum Loading Cart Load

6,613 lbs

Loading Height (Including Pallet)

7 in

Suction Area Folded In

4.72 in x 8.66 in

Suction Area Folded Out

4.72 in x 43. 31 in

Maximum Blank Size

123 in x 63 in

Minimum Blank Size

11.81 in x 7.87 in

Machine Length

255.51 in

Machine Height

209.72 in

Machine Weight

69,666 lbs

Work In Tandem With

Integrated Automation

From robotic integration to conveyor belt handling and raw material loading, connect your TruBend Center to other TRUMPF automation solutions for a true Smart Factory setup.

Tooling

Choose from TRUMPF’s wide selection of radius tools, custom bending tools, and precision options to match every application.

Extra Blank Holder Tools (ENW): Secure uniquely shaped or oversized workpieces.

Extra Bending Tools (ZBW): Achieve precise bends on complex profiles.

Horn Blank Holders: Handle asymmetrical or difficult part designs with ease.

Standard & Specialty Bending Tools: Adapt to diverse fabrication needs with TRUMPF's expansive tooling options.

Smart Software

Use TruTops Boost or TecZone Fold to simulate bending operations and program even the most complex parts in seconds. Reduce downtime and eliminate trial-and-error on the floor.

Automatically Power Through Every Bend

The TruBend Center 7030 is a complete, self-sufficient bending system that keeps productivity high, manual labor low, and output consistent, even as part complexity increases.