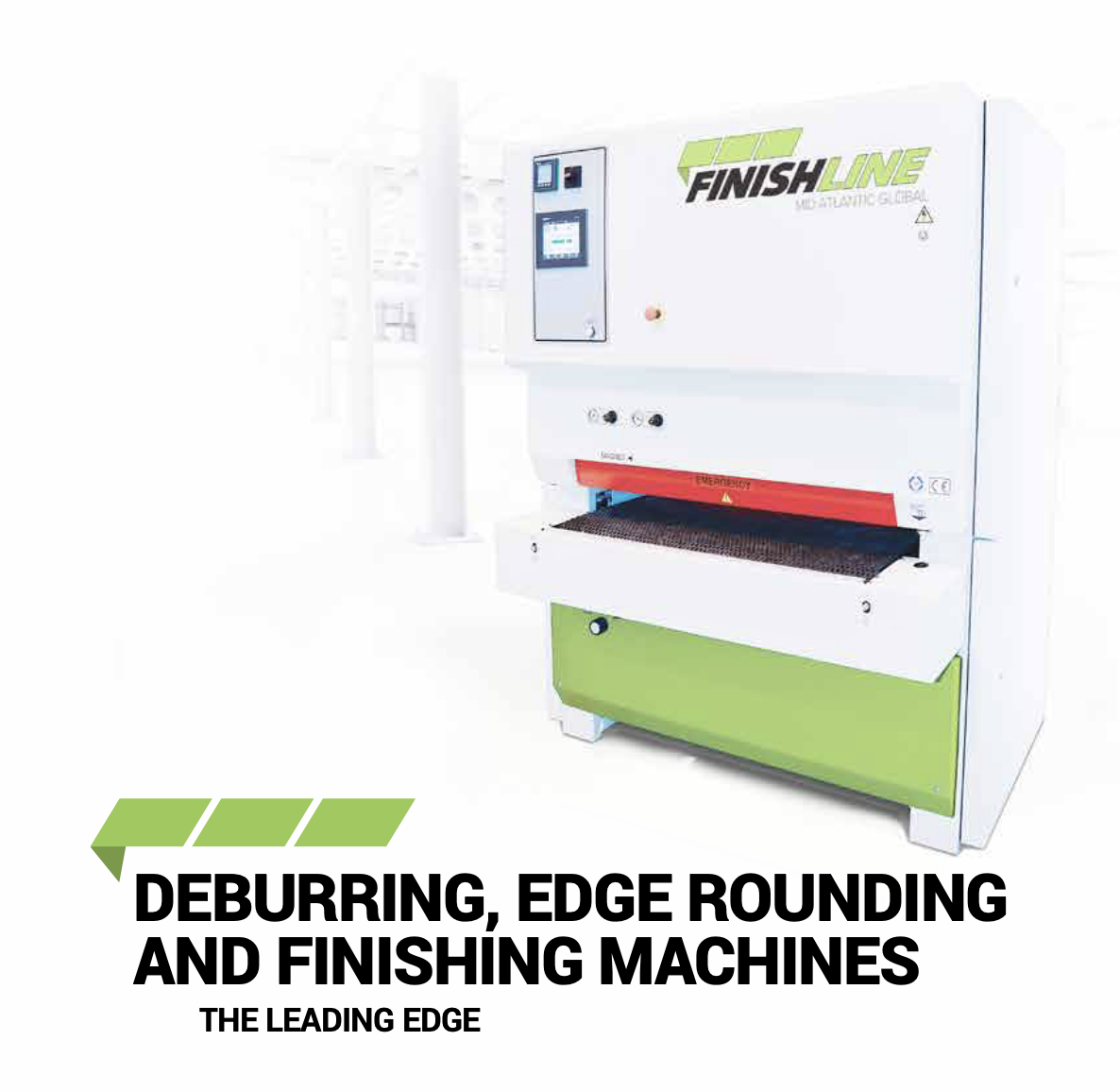

FINISHLINE: Intelligent Design. Uncompromised Quality.

Built for real-world fabrication, it handles deburring, edge rounding, oxide removal, slag removal, graining, and polishing - effortlessly. Whether your parts come off a punch, laser, plasma, or waterjet, FINISHLINE replaces hours of manual grinding with a consistent, repeatable finish that improves coating adhesion and operator safety.

With customizable configurations, intuitive controls, and proven reliability, FINISHLINE helps shops reduce labor costs, increase throughput, and deliver higher-quality parts faster. It’s the smarter way to achieve precision finishing - and a competitive edge - across every job you run.

Closing the Loop with TRUMPF + FINISHLINE

Complete Your Workflow with TRUMPF + FINISHLINE. TRUMPF handles cutting and forming with precision - FINISHLINE completes the process with automated deburring, edge rounding, oxide removal, slag removal, and graining.

FINISHLINE is a modular, all-in-one solution of industrial-grade metal finishing machines engineered for the demands of modern fabrication. Designed to handle every stage of post-processing, it efficiently performs deburring, edge rounding, oxide and slag removal, graining, and polishing - all in one compact system.

Supported by Maintecx and Mid Atlantic Global, FINISHLINE is built to adapt to your production environment. Whether you’re running high-volume production or short-run parts, there’s a FINISHLINE configuration to match your workflow and finishing goals.

FINISHLINE Overview: A Smarter Way to Finish Metal

FINISHLINE machines are available in multiple working widths and working units can be configured to your specific needs. Each system can include a combination of abrasive belts, rotary brushes, top brushes, and barrel brushes to achieve the desired finish quality for your application.

All models feature dry processing with vacuum, magnetic, or combination (vacuum + magnetic) worktables, making them suitable for both ferrous and non-ferrous materials. To maintain a clean, safe, and efficient work environment, FINISHLINE machines can be paired with a dedicated wet dust collection system that captures airborne particles and debris during operation.

Available Metal Finishing Machines Models & Configurations

Working Widths:

25.5”

43”

51”

63”

Key Configuration Options:

Wide Belt Head (R Unit) – Best for: Deburring and Graining

Surface Brushes (D Unit) – Best for: Edge Rounding, Oxide Removal, and Slag Removal

Surface Polisher (B Unit) – Best for: Consistent surface polishing

Rotary Unit (A Unit) – Best for: Aggressive Edge Rounding and non-directional surface finishing

Materials:

Mild Steel

Stainless Steel

Aluminum

Galvanized and Zinc-Coated Stock

Copper

Brass

Common Applications: Deburring, Edge Rounding, and Oxide Removal

FINISHLINE machines improve the surface quality of punched parts or parts cut from lasers, waterjets, and plasma cutting systems. With the right finishing setup, shops can reduce manual work, improve consistency and dramatically improve throughput, and prep parts for painting, welding, or customer delivery. This includes:

Deburring: Remove sharp edges after punching or cutting.

Edge Rounding: Add consistent radii to corners to improve part quality and coating adhesion.

Oxide Removal: Strip laser oxide layers for better paint and powder coat bonding.

Slag Removal: Remove built up slag from processing parts from a plasma cutter.

Surface Finishing: Reduce scratches and remove residue for a cleaner finish.

Typical parts include brackets and mounting plates, enclosures and chassis, electrical and control panels, signage and architectural panels, HVAC components and ductwork, and various OEM and contract-manufactured sheet metal parts.

Upgrade Your Finishing Line

We’ll walk you through the differences between models and help you configure the best FINISHLINE machine for your shop and applications. Contact us for a demo, to run your sample parts, request a quote, or explore your options with a FINISHLINE expert.