TRUMPF + transfluid: Smarter Tube Forming Automation

When it comes to tube fabrication, automation doesn’t stop at the machine. It’s what happens between the machines that makes a truly efficient system.

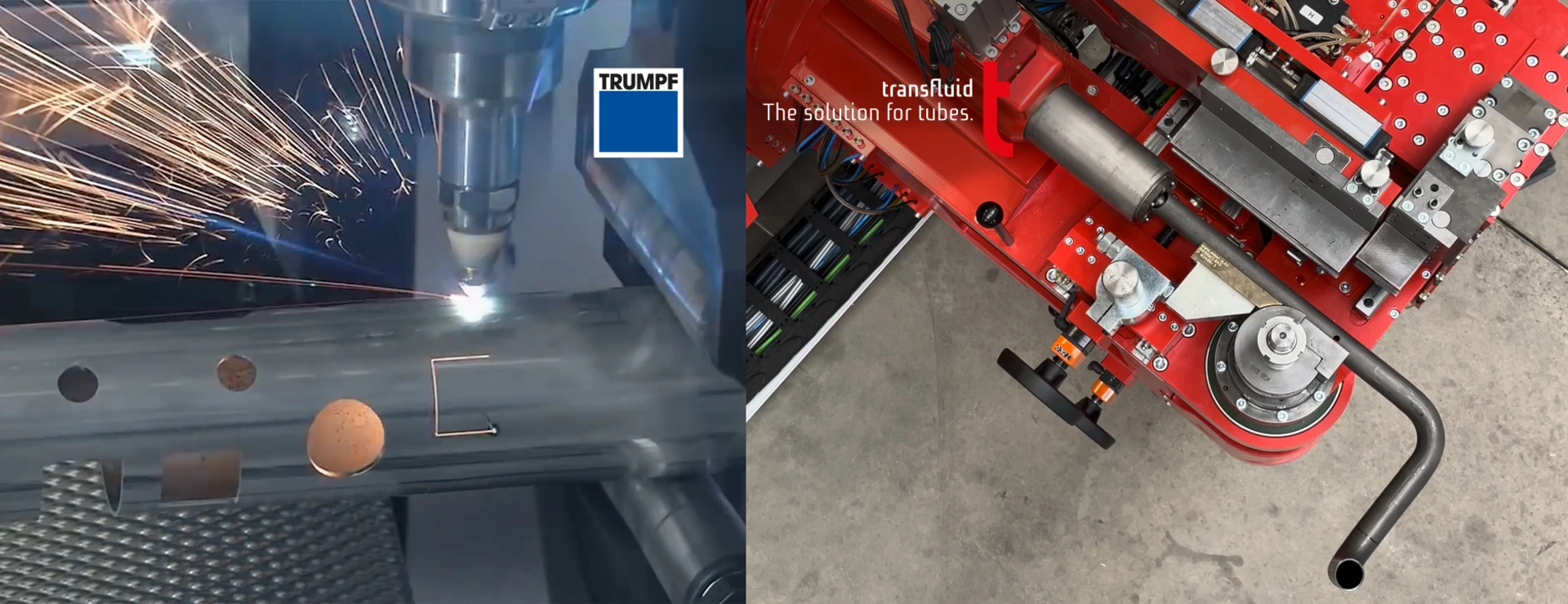

That’s where the TRUMPF and transfluid partnership comes together for seamless integration to tube forming processes. As TRUMPF’s automation partner for intermediate steps, such as bending, forming, and positioning, transfluid adds the missing link between machines. And through Maintecx, you get the full picture: expert guidance, implementation, and ongoing support from a single source.

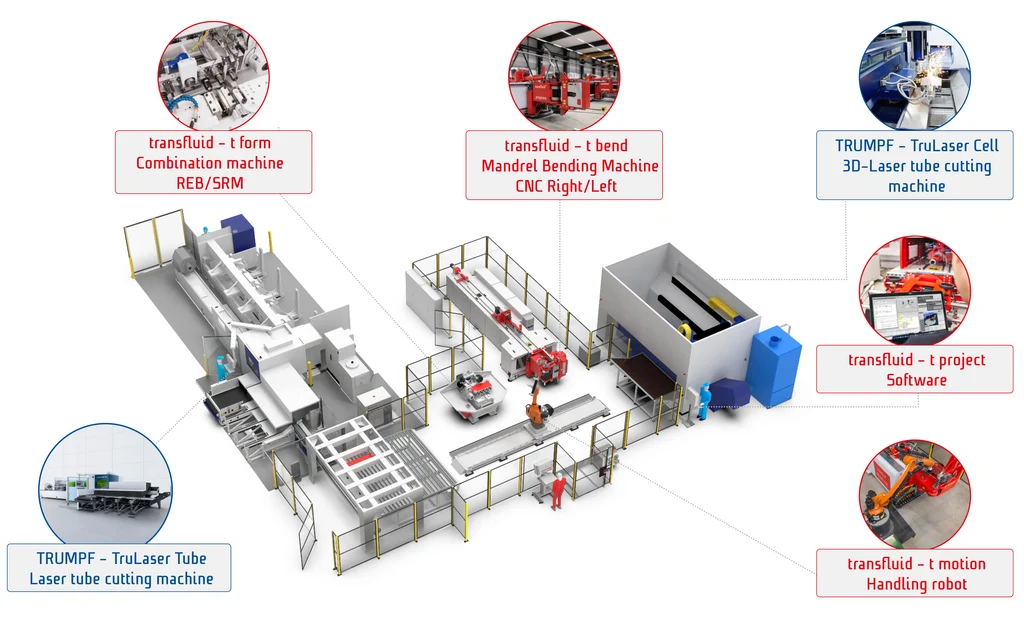

This partnership creates an end-to-end tube production solution that combines:

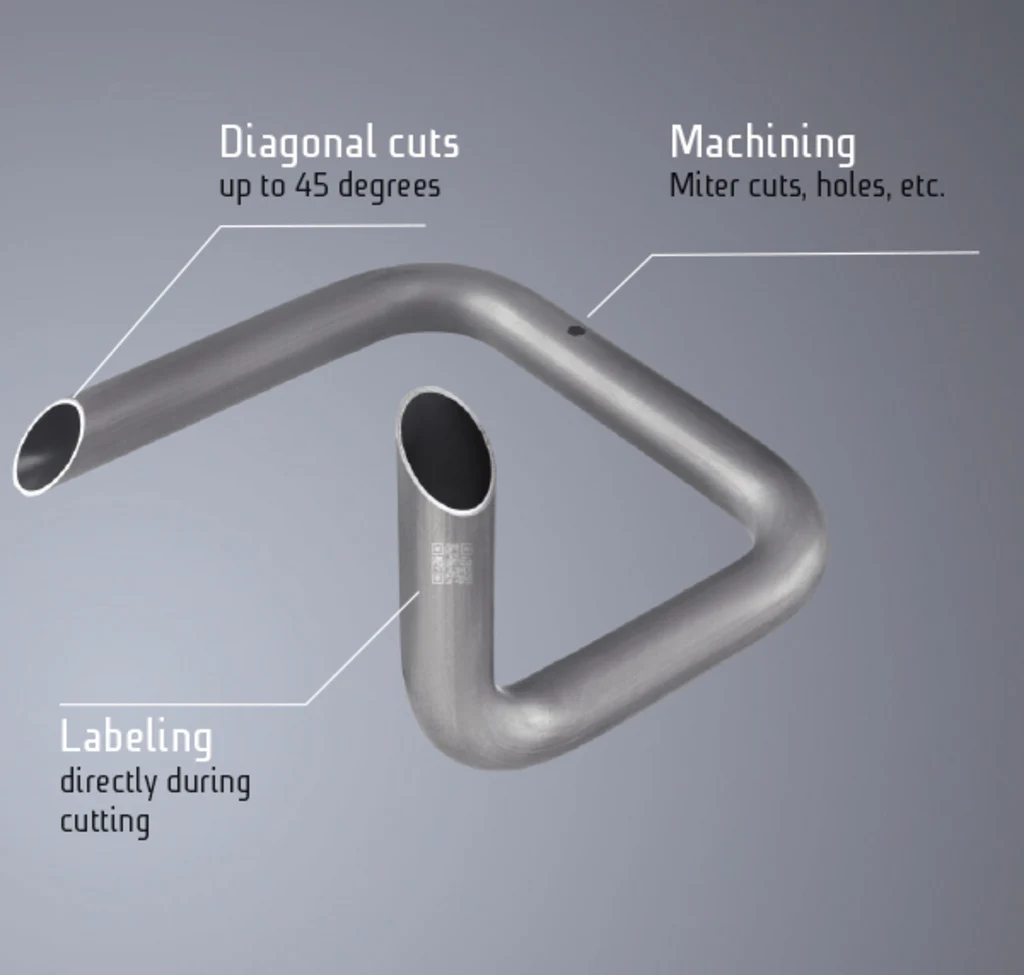

TRUMPF’s advanced laser tube cutting systems, known for precision and productivity

transfluid’s flexible forming and bending automation, designed to handle material transport, staging, and setup between processes

Together, they deliver a smarter, more connected workflow, from the first bend to the final cut.

What the TRUMPF–transfluid Partnership Offers

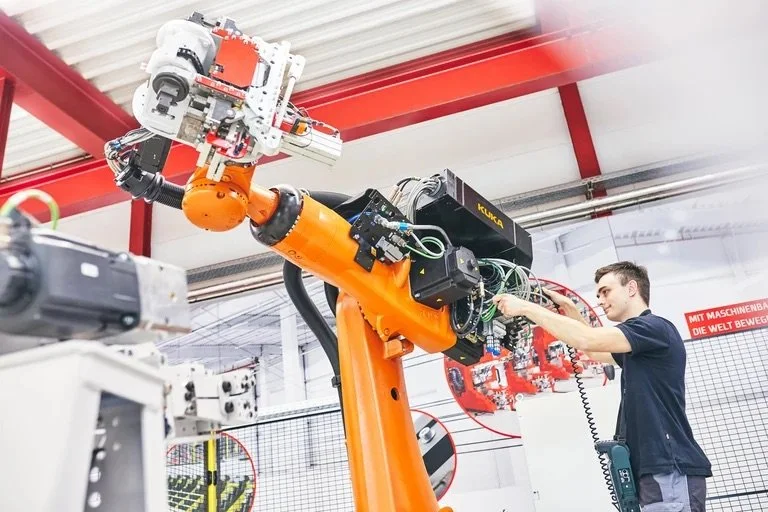

How transfluid Automates Between Processes

While TRUMPF handles the cutting, transfluid’s specialty is what happens before and after. Their automation systems can:

Move and align tubes between bending, forming, and cutting machines

Handle part identification, staging, and sorting

Integrate robotics, conveyors, and material-handling equipment into a unified cell

Connect seamlessly with TRUMPF systems to reduce manual intervention and improve throughput

Whether you’re running small batches or high-volume production, this integrated approach improves cycle time, accuracy, and repeatability across your shop floor.

A Smarter Workflow, Built for Production

By automating the “in-between” steps in tube processing, the TRUMPF + transfluid setup gives fabricators:

Faster transitions between forming and cutting

Lower labor costs and fewer errors

Better part traceability and quality assurance

A future-proof system that’s ready to scale

Industries That Benefit

This solution is ideal for any manufacturer that relies on high-precision tubing components, including:

Automotive

Aerospace

HVAC and mechanical systems

Furniture and metal fabrication

Agriculture and construction equipment

Work with Maintecx to

Build Your Ideal System

Maintecx is your automation partner. Our team will help you evaluate your current workflow, recommend the right combination of TRUMPF and transfluid technologies, and support you through installation, training, and service. From concept to commissioning, we help you build a more efficient, more productive shop. Contact us to explore TRUMPF + transfluid automation solutions.