TRUMPF TruBend Series 7000

Compact Power for Precision Bending

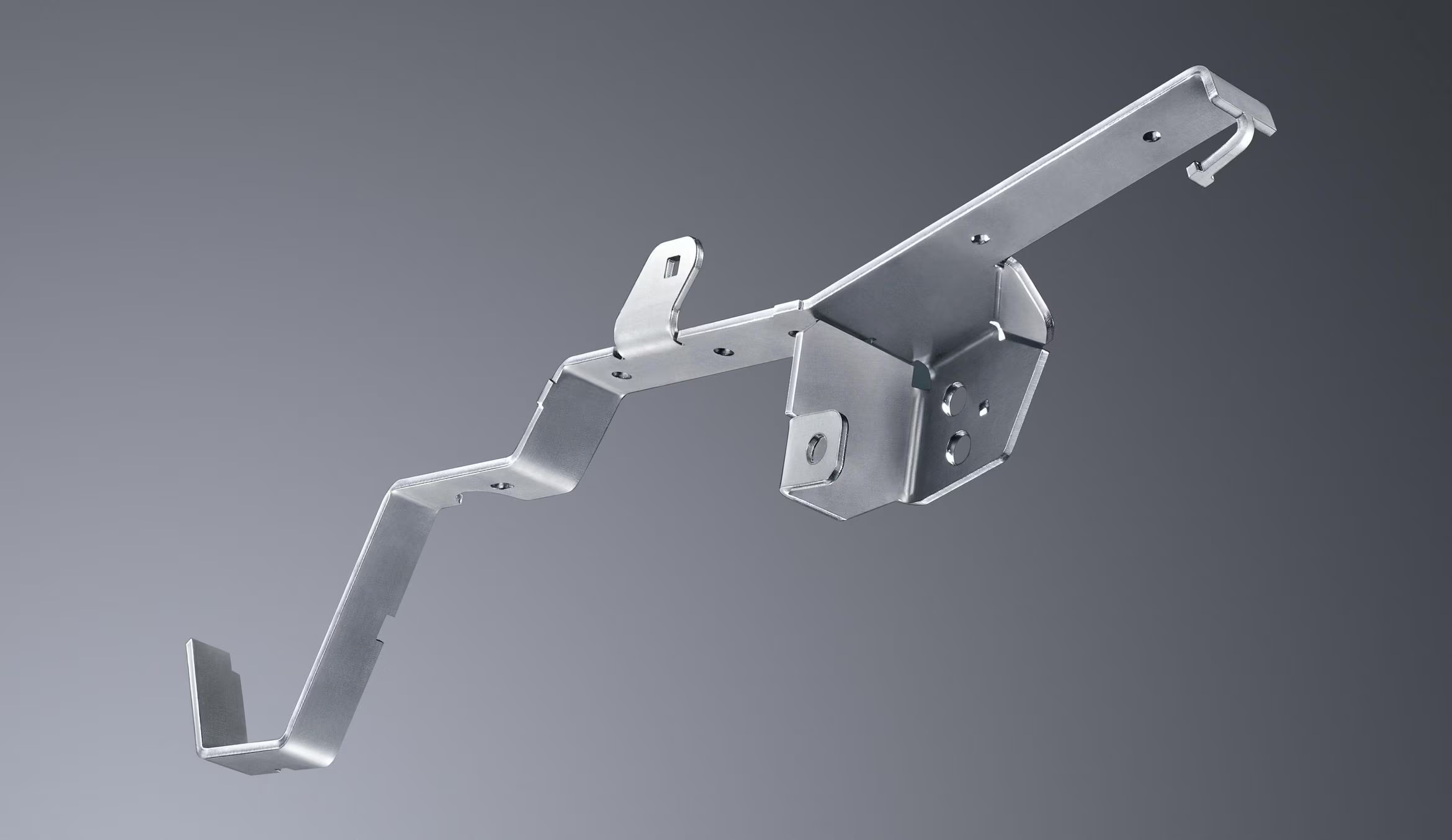

The TRUMPF TruBend Series 7000 is a compact, high-speed bending machine that delivers ergonomic performance and unbeatable precision. Designed for bending small and medium-sized parts, this machine is the ideal solution for shops looking to optimize productivity in tight spaces without sacrificing TRUMPF-level quality.

Key Features

Compact & Ergonomic Design: Engineered for operator comfort and minimal footprint, making it ideal for lean manufacturing cells or smaller shop floors.

High-Speed Precision: Rapid axis movements and exact positioning make this series one of the fastest and most accurate bending machines on the market.

Touchscreen Control & Smart Setup: Simple, intuitive programming with user-friendly interface and fast tool change capabilities.

Energy Efficient Operation: Standby mode and dynamic servo drive reduce energy consumption during idle and active operation.

Automated Option Available: For even higher output, pair with the TruBend Cell 7000, a fully automated bending cell built for fast, repeatable production.

Applications

The TruBend Series 7000 is perfect for fabricators working with:

Small-Format Sheet Metal: Ideal for precision parts used in electronics, medical devices, and HVAC components.

High-Mix, Low-Volume Runs: Rapid setup time supports frequent part changes with minimal downtime.

Automation-Driven Production: The system can scale with your automation needs as demand grows.

Machine Variants

TruBend 7036

Compact, high-speed bending machine ideal for small parts and lean production setups. With ergonomic features and fast cycle times, it’s a go-to option for precision in tight spaces.

View Technical Data

Press Force

40 tons

Bending Length

40 in

Width Between Columns

36.7 in

Usable Open Height

11.6 in

Throat Depth

5.9 in

User Interface

Touchpoint TruBend

Length

74.8 in

Width

52.8 in

Height

93.7 in

TruBend 7050

Designed for larger or thicker workpieces and offering higher press force and bending length, this variant is perfect for applications needing more power without compromising on speed or efficiency.

View Technical Data

Press Force

55 tons

Bending Length

60 in

Width Between Columns

51.4 in

Usable Open Height

15.2 in

Throat Depth

9.8 in

User Interface

Touchpoint TruBend

Length

95.3 in

Width

71.1 in

Height

101.6 in

Work In Tandem With

Scalable Automation with Flex Cell

Looking to automate without a full system overhaul? The Flex Cell transforms your manual TruBend 7050 into a high-speed, compact bending cell that handles simple parts automatically.

Quickly switch between manual and automated production

Ideal for shops needing flexibility without sacrificing speed

Compact design fits seamlessly into space-conscious production environments

Versatile Bending Tools

Customize your bending setup with TRUMPF’s comprehensive tooling options designed for efficiency, precision, and operator comfort:

Standard Tools: Choose from over 150 upper and lower tool types tailored to your needs.

Lightweight Tools: Up to 30% lighter for tools under 12 inches long, equipped with Safety-Click for faster, safer setup.

ZN Tools: Prevent cold welding and zinc buildup on galvanized sheets with LASERdur ZN-coated tools and no cleaning required.

Custom Tools: TRUMPF can develop specialized tools for unique applications, tested with your materials for quality assurance.

Smart Software Integration

Pair the TruBend Series 7000 with TruTops Boost, TRUMPF’s all-in-one solution for intelligent 3D design and bending programming.

Automatically generate bend programs based on your part design

Eliminate time-consuming routines with smart automation

Apply best practices using TRUMPF’s built-in ruleset and technical knowledge

Get a Quote for the

TRUMPF TruBend Series 7000

Ready to bend more in less space? Contact Maintecx today to request a quote on the TruBend Series 7000 or learn more about how it fits into your production workflow.