TRUMPF TruBend Series 3000

Economical Precision Bending Machines

The TRUMPF TruBend Series 3000 combines high-quality TRUMPF engineering with user-friendly operation and an attractive price-performance ratio. Designed for cost-effective production, these machines deliver precise results and uphold the highest safety standards even at low utilization rates. With fast tool changes, a precise backgauge, and the ACB Laser angle measuring system, the TruBend Series 3000 ensures perfect angles from the first part.

Key Features

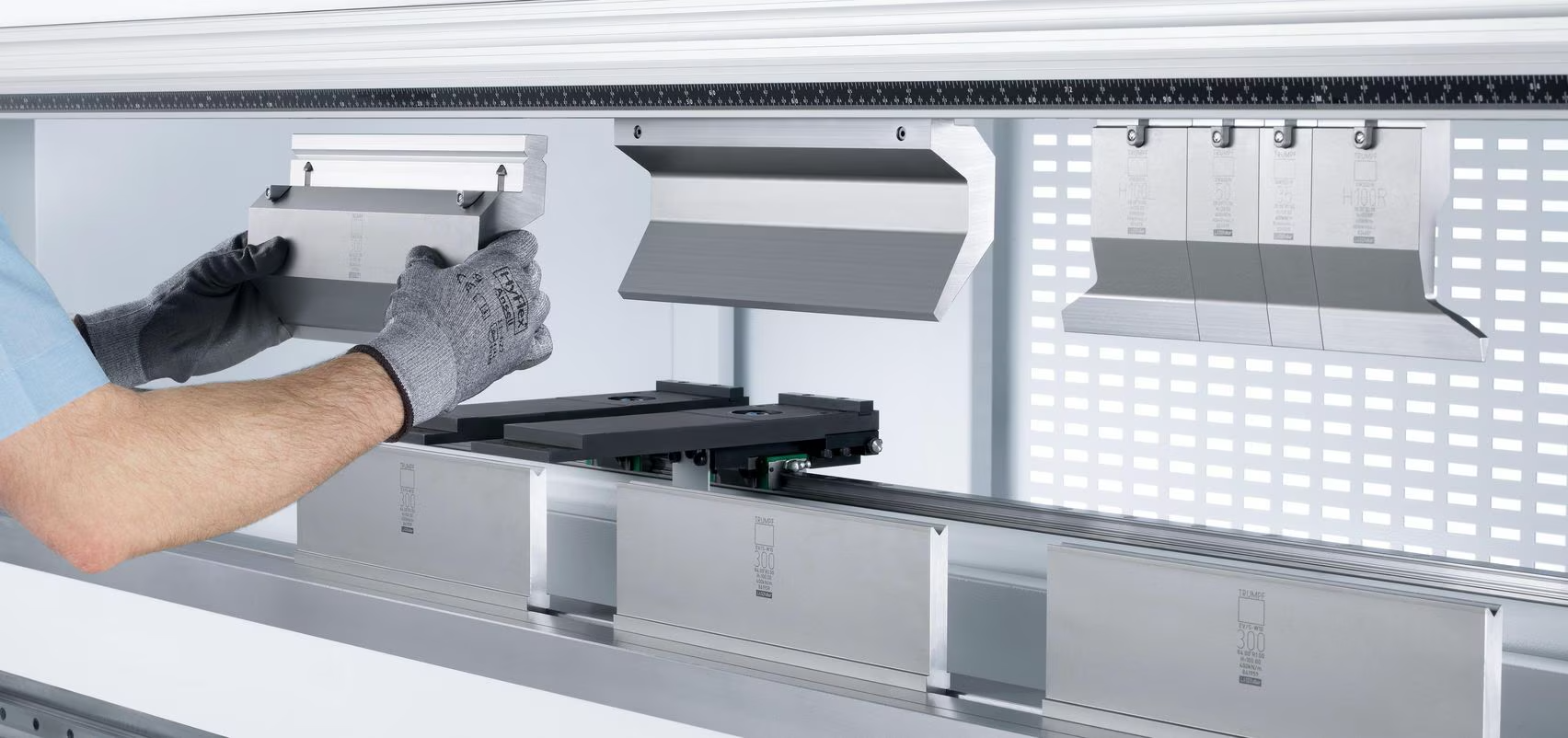

Fast Tool Changes: Choose between manual, quick-clamp, or hydraulic tool clamping systems for complete flexibility and reduced setup times.

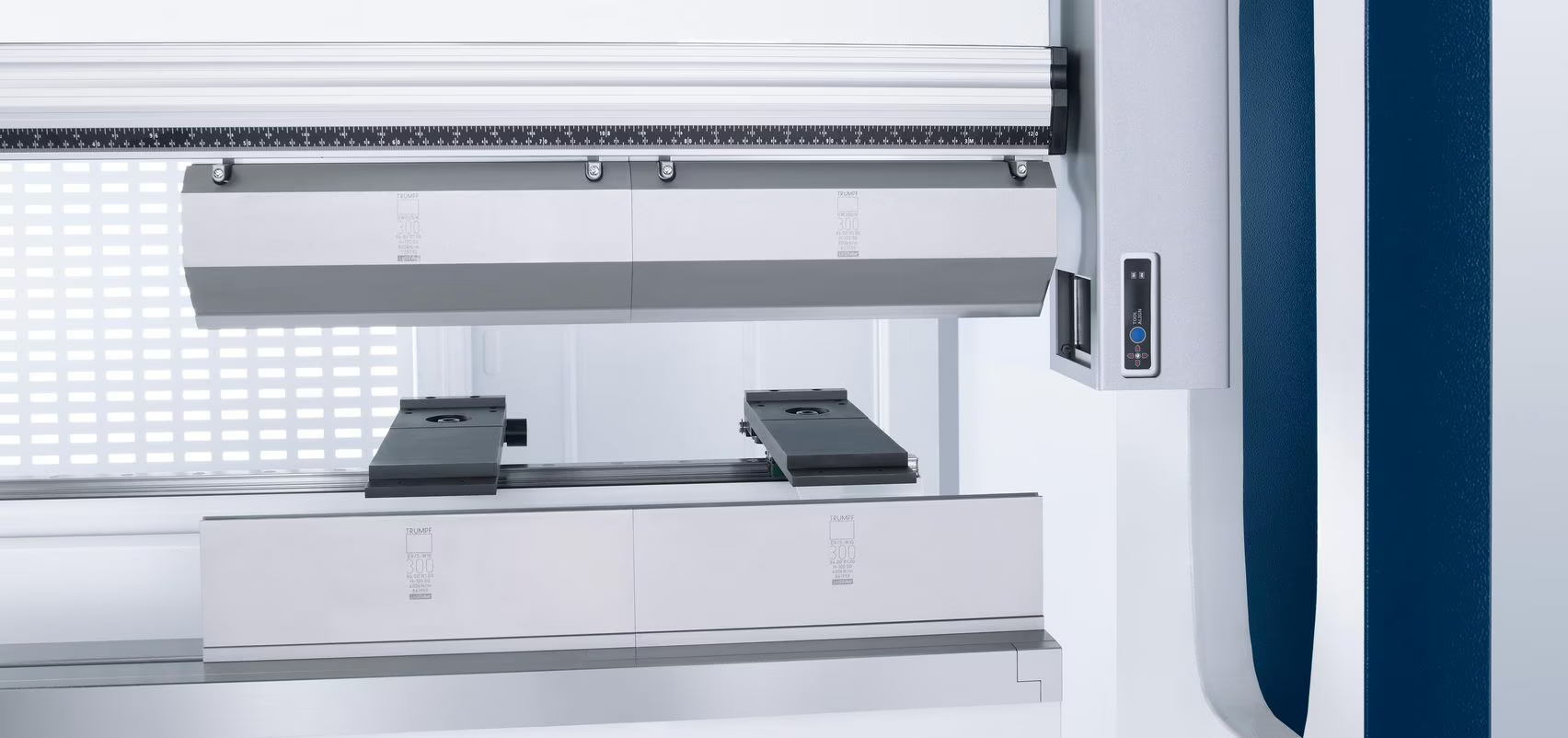

Precise Backgauge: Select a 2-, 4-, or 5-axis backgauge to position blanks accurately for exact side lengths and accommodate complex part geometries.

ACB Laser Angle Measuring: Achieve perfect angles from the first part with the non-contact, optical ACB Laser system that projects a line onto the sheet and detects angles via camera.

Compact Design: The closed frame allows unrestricted use of the entire bending length, and the symmetrical force distribution ensures consistent results.

User-Friendly Control: The multi-touch control system is clearly organized, straightforward, and self-explanatory, simplifying operation and programming.

Applications

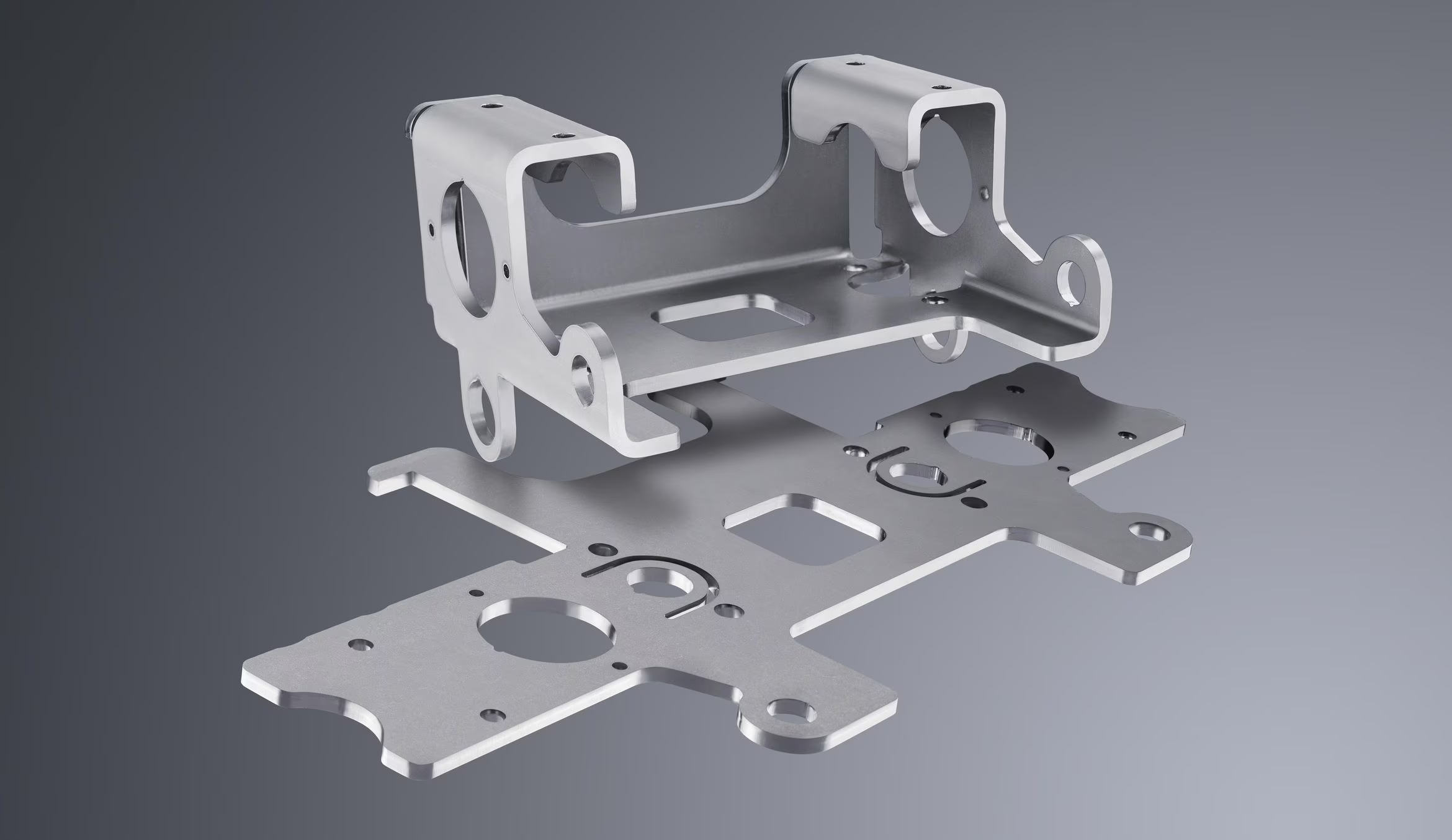

The TruBend Series 3000 is designed to provide reliable bending performance for a broad range of standard fabrication tasks, including:

Sheet Metal Enclosures

Brackets & Structural Components

General Job Shop Fabrication

Light to Medium Gauge Parts

Agricultural & Utility Equipment

Machine Variants

TruBend 3066

The TruBend 3066 is the most compact model in the Series 3000 lineup, offering a press force of 660 kN (148,517 lbf) and an 80-inch bending length. Ideal for fabricators focused on smaller parts or limited shop space, this model delivers precision and performance for everyday bending jobs with fast cycle times and a lower footprint.

View Technical Data:

Press Force

72.6 tons

Bending Length

80 in

Width Between Columns

93 in

User Interface

T3500T multi-touch

Max Speed Y Axis, Rapid Downward

7.87 in/s

Max Speed Y Axis, Operation

0.59 in/s

Length

101.85 in

Width

64.72 in

Height

93.31 in

Weight

12,457 lbs

Weight (Enlarged Version Option)

–

TruBend 3100

With a 1000 kN (224,809 lbf) press force and a 120-inch bending length, the TruBend 3100 is a versatile mid-range option. It’s perfect for a wide range of medium-to-large-sized parts and production runs. Whether you’re working on enclosures, chassis, or brackets, the 3100 offers the power and efficiency to keep up with growing demand.

View Technical Data:

Press Force

110 tons

Bending Length

120 in

Width Between Columns

133.25 in

User Interface

T3500T multi-touch

Max Speed Y Axis, Rapid Downward

–

Max Speed Y Axis, Operation

0.59 in/s

Length

141.93 in

Width

64.72 in

Height

93.31 in

Weight

16,975 lbs

Weight (Enlarged Version Option)

18,298 lbs

TruBend 3170

Engineered for high-capacity bending, the TruBend 3170 boasts 1700 kN (382,202 lbf) of press force and over 160 inches of bending length. This heavy-duty variant is built for fabricators who handle large-format sheets or thick materials. Its robust frame and advanced control make it ideal for demanding applications in structural, industrial, and architectural metalwork.

View Technical Data:

Press Force

187 tons

Bending Length

160.6 in

Width Between Columns

173.4 in

User Interface

T3500T multi-touch

Max Speed Y Axis, Rapid Downward

–

Max Speed Y Axis, Operation

0.59 in/s

Length

182.91 in

Width

64.72 in

Height

115.16 in

Weight

33,069 lbs

Weight (Enlarged Version Option)

–

Work In Tandem With

Tooling

The TruBend Series 3000 is compatible with a full range of TRUMPF tooling. Choose from over 150 standard upper and lower tools to customize your setup, or opt for lightweight tools that reduce handling time and strain for operators. For galvanized material, LASERdur ZN tools prevent zinc buildup and cold welding. Need something specialized? TRUMPF also offers custom tool solutions that are pre-tested with your materials.

Software Integration

With TecZone Bend, programming your bending operations has never been faster or easier. This powerful software automatically generates a complete bending program, including the NC code, from 2D or 3D data in seconds. Whether you're programming from the office or directly at the machine, TecZone Bend speeds up production, reduces errors, and keeps a smooth path from design to finished part.

Get a Quote for the TRUMPF TruBend Series 3000

Enhance your bending capabilities with the TRUMPF TruBend Series 3000, offering precision, efficiency, and safety. Contact Maintecx today to learn more about pricing and availability.