Laser Tube Cutting Machines

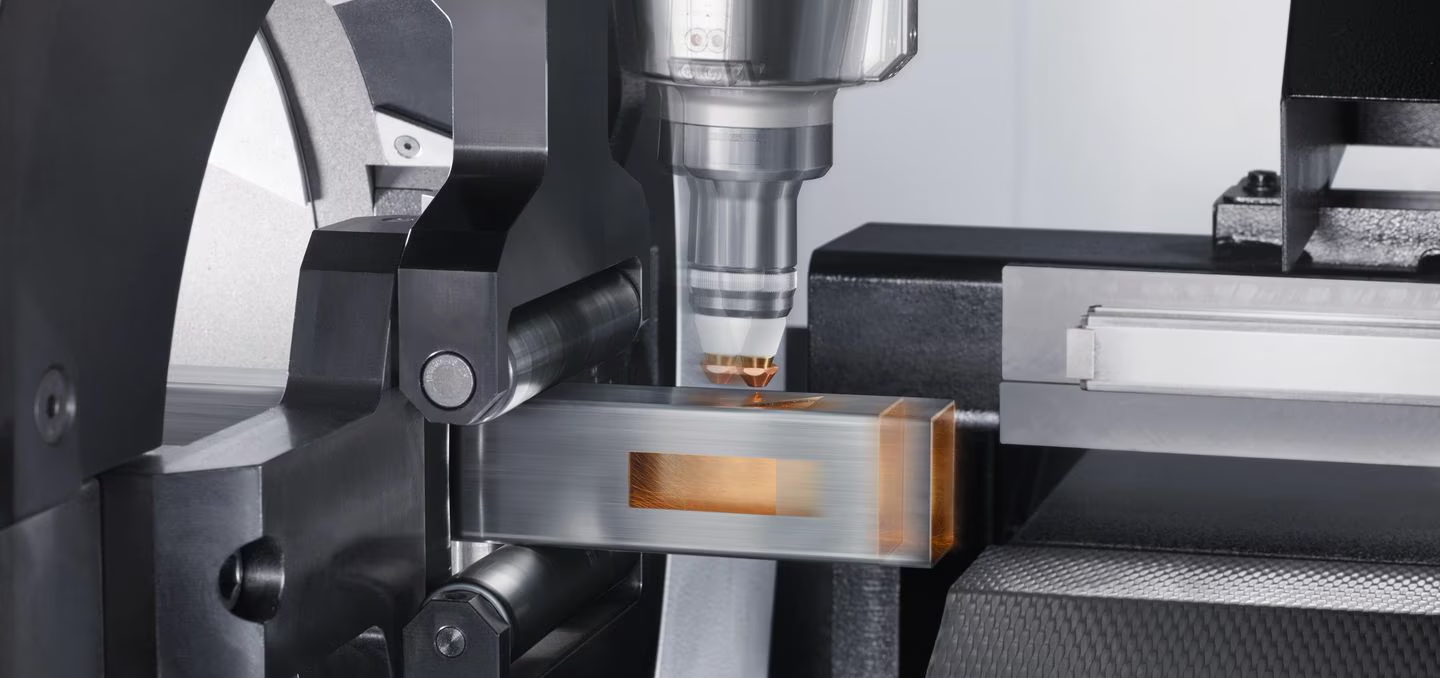

From mechanical engineering to architecture and furniture manufacturing, laser-cut tubes and profiles are shaping the next generation of design and production. TRUMPF’s TruLaser Tube series brings that precision to every shop, with high cutting speeds, an automation-ready design, and unmatched versatility for round, square, rectangular, and special profiles.

Maintecx helps fabricators choose, configure, and integrate TRUMPF laser tube cutting machines that align with their specific materials, production volumes, and automation goals.

Explore Our TRUMPF Laser Tube Cutting Machines

An affordable entry into laser tube cutting with a compact design, efficient operation, and intuitive controls.

Cut mild steel, stainless, and aluminum with exceptional edge quality. Smart automation options and quick setup keep productivity high even in short runs.

Offering the largest work envelope, the highest laser power, and seamless automation integration, this laser tube machine is engineered for heavy-duty tube processing and 24/7 operation.

Why Fabricators Choose TRUMPF & Maintecx

TRUMPF laser tube cutting machines deliver clean cuts while transforming how shops handle tube fabrication.

All-in-one cutting: Replace sawing, drilling, and milling with a single automated process.

Design freedom: Complex contours, angle cuts, and bevels made easy for stronger, lighter assemblies.

High-speed performance: Fiber laser power delivers faster cuts with less heat distortion and lower energy use.

Automation-ready: Load, unload, and sort tubes automatically to keep material moving around the clock.

Connected production: Integrate with TruTops software for programming, nesting, and job sequencing.

Maintecx expertise: Our team helps you align TRUMPF tube-cutting solutions with your workflow, part mix, and ROI targets.

Choosing the Right TRUMPF Tube Cutting Machine

Every fabricator’s needs are different, whether you’re cutting thin-walled tubes for furniture or thick, structural profiles for construction. Here’s a quick guide to help you find your fit:

New to tube cutting: The TruLaser Tube 3000 Fiber offers reliable, cost-effective entry-level performance.

High-mix production: The TruLaser Tube 5000 Fiber balances speed, precision, and flexibility for shops with diverse jobs.

Heavy-duty applications: The TruLaser Tube 7000 Fiber provides maximum power, range, and automation for continuous production.

Need more tailored guidance? Talk to a Maintecx expert

FAQs About Laser Tube Cutting Machines

-

Mild steel, stainless steel, aluminum, copper, and brass are all cut cleanly using TRUMPF fiber laser technology.

-

Round, square, rectangular, oval, and custom shapes are all supported.

-

Laser cutting eliminates secondary machining steps, delivers tighter tolerances, and supports complex geometries impossible with saws or drills.

-

Yes. Systems can include automatic loading, unloading, and sorting for continuous “lights-out” operation.

-

As a TRUMPF partner, Maintecx provides local installation, training, and lifecycle support, ensuring your system performs at peak capacity from day one.

Learn More About Tube Laser Cutting

-

Technology Highlight: TRUMPF Laser Tube Cutting Machines

Upgrade Your Laser Tube Cutting Operation

We’ll walk you through the differences between models and help you configure the best Laser Tube Cutting machine setup for your shop and applications. Contact us to request a quote or explore your options with a Maintecx Rep.