Automated Industrial Storage Systems for Fabrication

Maintecx delivers high-performance industrial storage systems designed by TRUMPF and STOPA to transform your material handling, save space, and accelerate production. From compact, modular designs to large-scale, fully automated warehouses, our solutions provide real-time inventory visibility and seamlessly integrate with your cutting and bending machines.

By optimizing your storage, you eliminate wasted time searching for materials, reduce setup time, and ensure materials are staged when and where they are needed, making your entire production sequence faster, safer, and more efficient.

Explore Our TRUMPF & STOPA Automated Storage Systems

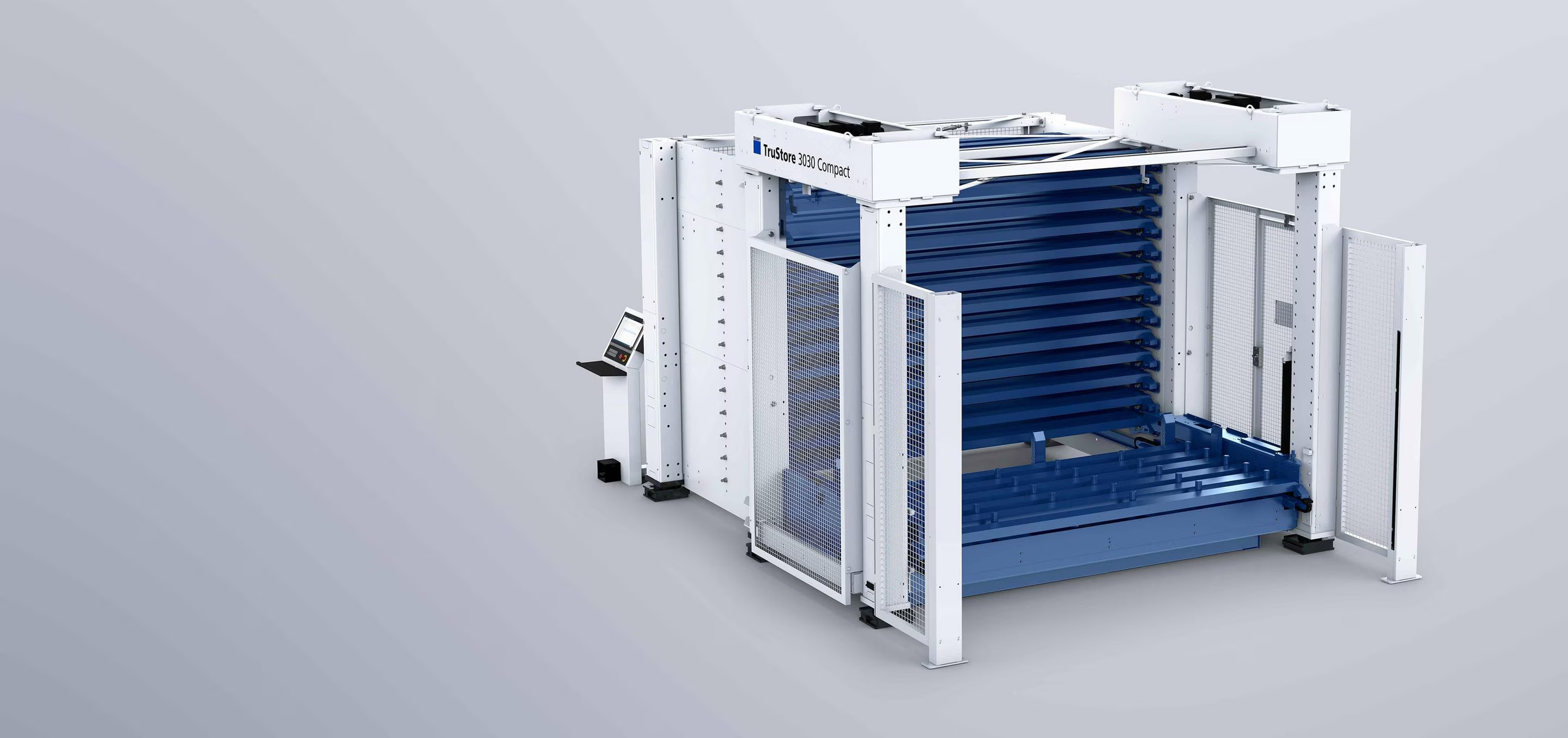

The perfect start in the world of TRUMPF storage technology: Reliable and economical, the tower storage system of the TruStore Series 3000 Compact makes it easier for you to get started with unattended production.

A fully automated, scalable storage system built for high-volume efficiency. The TruStore 3000 drastically reduces space requirements and can be developed into a comprehensive, fully automatic system for high-volume storage, integrated directly into your laser cutting and production flow.

Designed to handle the massive range of tasks required of a full logistics center. STOPA systems manage large-format material and serve as central, integrated steel storage systems for your entire facility, minimizing material movement and maximizing throughput.

Why Automated Storage is Essential for

Smart Factory Optimization

Choosing the right storage solution from Maintecx is a direct path to higher productivity and lower operating costs. Storage systems offer critical advantages that are foundational for modern, connected production:

Real-time Inventory Control: Know the exact location and quantity of every sheet of metal in real time. This eliminates stock discrepancies, speeds up material staging, and optimizes raw-material purchasing decisions.

Seamless Automation: Modular design allows for simple integration with automatic sheet loaders and AGVs, enabling lights-out production and minimizing manual handling.

Space Optimization: These highly compact, vertical systems minimize the facility footprint required for bulk material storage, reclaiming valuable floor space for high-value machinery.

Data-Driven Efficiency: By integrating with software like TRUMPF TruTops, the system ensures the right materials are pulled at the right time, streamlining the entire fabrication sequence and reducing machine idle time.

Choosing the Right Industrial Storage System

Whether you're organizing a small area or automating your entire facility, there is a modular solution designed to meet your production volume:

Growing Shops: The TruStore Series 1000 provides immediate organization and space saving for shops moving beyond manual racks and beginning their automation journey.

High-Volume/Mixed Production: The TruStore Series 3000 is scalable and designed for facilities requiring automated management and high integration with fabrication machines.

Large-Format/High-Capacity Logistics: STOPA systems handle the highest throughput and capacity, managing massive quantities of industrial metal storage systems and serving as the central nervous system for complex logistics operations.

Need expert guidance on integrating automated storage into your workflow? Talk to a Maintecx expert

FAQs About Automated Storage Systems

-

The main benefit is optimization. You save floor space by using vertical storage, reduce labor time by automating material retrieval, and increase machine utilization by ensuring material is staged reliably and on demand.

-

They are primarily designed for flat sheet metal (mild steel, stainless steel, aluminum), but can be configured to store other materials, such as remnant pieces, tools, or long goods, depending on the model.

-

Yes. The TruStore and STOPA systems are designed to integrate seamlessly with TRUMPF laser cutters, bending machines, and other production processes via the TRUMPF Smart Factory ecosystem, ensuring a smooth, fully connected material flow.

Learn More About Storage Systems

-

Common Bottlenecks in Metal Fabrication & The Machines That Can Eliminate Them

-

How To Reduce Manufacturing Costs With TRUMPF

-

Your ERP Isn’t the Problem. Your Factory Layout Is.

Upgrade Your Storage Systems

We’ll walk you through the differences between models and help you configure the best Storage System layout for your machines and your shop. Contact us to request a quote or explore your options with a Maintecx Rep.