Smarter Tube Bending Starts Here: What Makes transfluid Stand Out

Legacy tube benders weren’t built for today’s complex, multi-radius geometries or the new speed production lines demand. transfluid helps solve these modern fabrication challenges with CNC-powered systems that combine automation, intelligence, and flexibility to transform the way your shop bends tubing. These machines were built for manufacturers who can’t afford to babysit their bending process.

Whether you’re trying to simplify programming, cut scrap rates, or adapt to evolving part designs, transfluid delivers the precision and speed traditional hydraulic or even older CNC benders can’t match. Here’s what sets them apart, and how Maintecx can help you bring that power to your shop.

Why Smart Tube Bending Matters

If you’re still bending tube the old-fashioned way, you’re likely spending too much time setting up, too much money dealing with scrap, and too much energy trying to meet tighter tolerances on more complex parts. With labor shortages and faster changeovers, shops need to do more with fewer hands, less time, and tighter specs.

Traditional hydraulic benders have long been the workhorse of many fab shops, but their limitations are showing:

Long setup times for each new part

Manual programming and adjustment

Trial-and-error correction

Inconsistent accuracy on complex shapes

High scrap rates from inaccurate bends

Limited support for multi-radius or variable wall parts

These limitations aren’t sustainable when you're under pressure to produce faster, with fewer operators and tighter tolerances. You need a system that can bend and think.

What Makes transfluid CNC Tube Benders Different?

transfluid CNC tube benders solve the problems that hydraulic and legacy systems can’t. They’re intelligent machines that adapt to what you’re building.

What sets transfluid apart:

Visual programming: No need to manually calculate bend sequences. Use visual modeling tools to simulate bends before production starts.

Real-time correction: Built-in sensors monitor every bend and adjust as needed, so one off-target part doesn’t turn into a full batch of scrap.

Digital twin simulation: transfluid’s software lets you test your program digitally, checking for collisions, wrinkling, and deformation before the machine even moves.

Multi-radius and complex profiles: Precision bending for elliptical tubes, variable wall thickness, or parts with multiple bend radii.

This isn’t just CNC. It’s CNC with brains and real advantages for your shop, including faster setup, higher repeatability, and better parts overall.

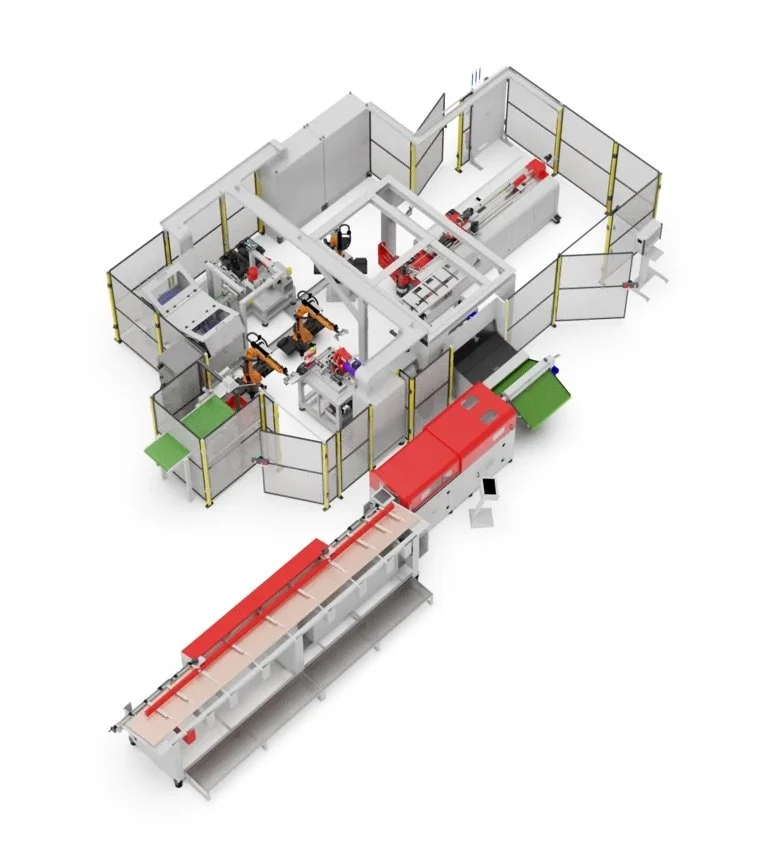

Automation Without the Hassle: t-motion + t-form

transfluid’s automation modules bring even more power to the floor without complicating your process. It makes lights-out manufacturing feel less like a dream and more like daily operations. With modules like t-motion, you can automate material handling, tool changes, and part transitions, while still maintaining tight process control.

Add-on automation options include:

Automated tool changeovers between part programs with no manual swaps

Robotic positioning and part handling for faster, safer operations

Integrated loading and unloading systems to keep material flowing without intervention

t-form end-forming systems for expanding, flaring, and other end treatments, all in the same line

Instead of multiple workstations, setups, and operators, these options give you one smart line that does it all. Whether you’re running five different part types or 500 of the same one, you get consistent results, and operators aren’t tied to the machine every step of the way.

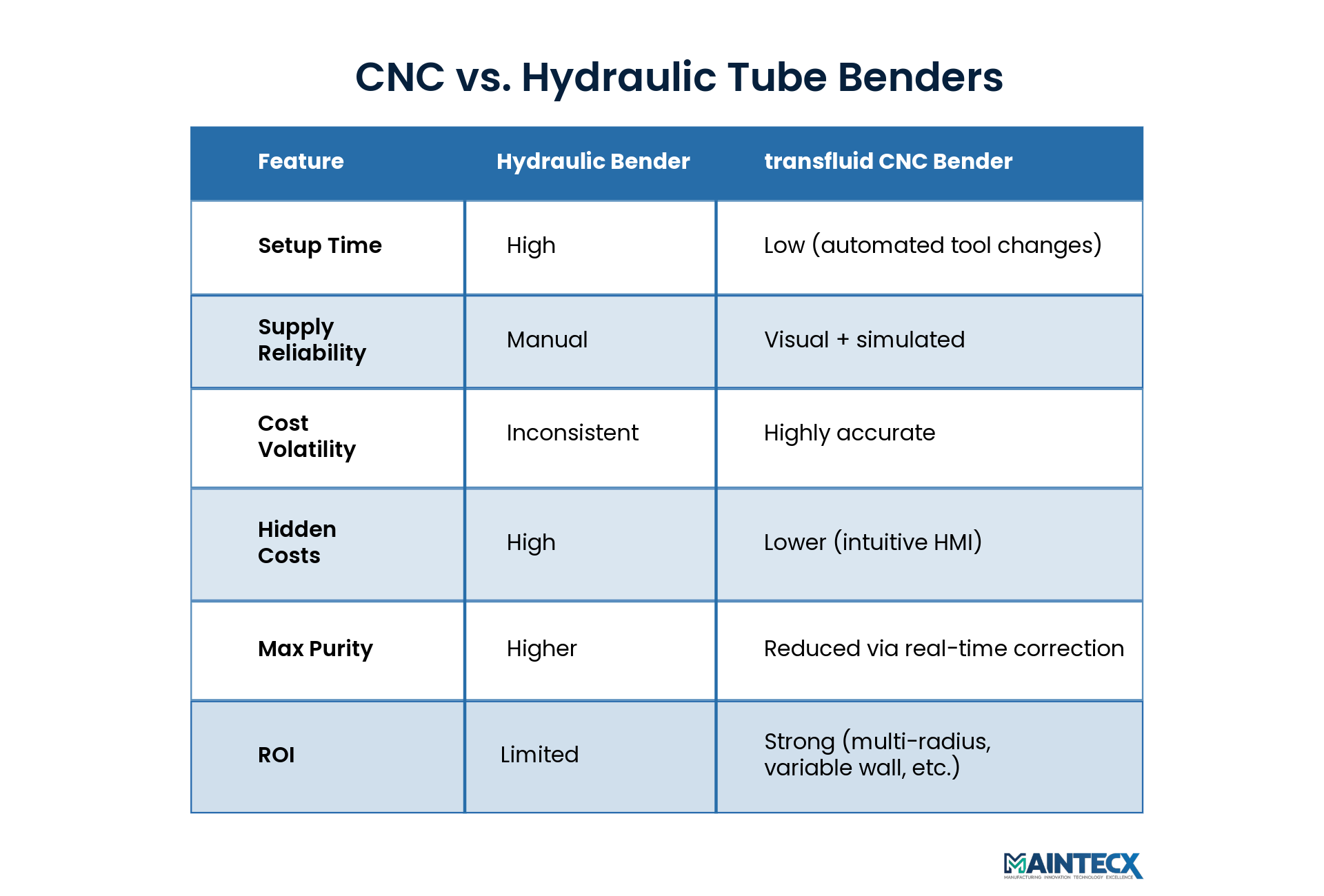

Better Than the Rest: CNC vs. Hydraulic Tube Benders

Still wondering if it’s worth making the switch? Here’s a quick breakdown of what life looks like before and after transfluid:

Switching to CNC may sound like a big step, but with transfluid, the learning curve is short, the ROI is clear, and the uptime speaks for itself. It gives your team room to focus on what really matters: making more and wasting less.

The TRUMPF + transfluid Advantage

transfluid doesn’t operate in a silo, and neither should your shop. Thanks to their partnership with TRUMPF, transfluid benders can be seamlessly integrated into full laser tube cutting workflows. That means:

Unified part libraries across machines

Faster transitions from laser to bender

Collision-checked digital twins from cut to form

Compatibility with Industry 4.0 platforms for smarter data sharing

It’s all part of a smarter factory approach that Maintecx helps bring to life every day.

Ready to Upgrade Your Tube Bending?

Whether you’re replacing an aging hydraulic bender or planning your next smart production cell, transfluid gives you the flexibility, intelligence, and control to take your operation to the next level.

Maintecx is the exclusive Upper Midwest provider of transfluid systems. We’ll help you spec the right system, train your team, and keep things running for the long haul. Explore our transfluid bending solutions or contact us today to request a quote.