Precision Tube-End Forming with transfluid tForm & TRUMPF

In tube fabrication, the ends often make or break the part. Whether you need a mirror-finish flare, a precise thread, or a multi-step profile that holds up under pressure, the transfluid tForm line delivers high-precision end-forming automation designed to keep up with modern production demands.

With seamless integration into TRUMPF tube cutting and bending systems, tForm machines help eliminate manual handling, reduce rework, and build repeatability into your production process. And with Maintecx as your automation partner, you get everything from application engineering to after-sales support under one roof.

tForm Machines for Every Forming Challenge

Each tForm machine is built to solve specific challenges in tube-end forming. Here's how they break down:

UMR Rollforming Machines

Designed to craft perfect sealing surfaces and flares with short clamping lengths (from 1× diameter), the UMR handles up to Ø 325 mm with fast tool changes and mirror-quality finishes. Ideal for automotive fuel lines, HVAC flare connections, and polished appliance tubing.

SRM Rollforming Machines

The SRM packs forming, cutting, post-bending cutting, and threading into one machine. High RPM and minimal tool change capacity make it ideal for demanding specs and complex profiles. Ideal for HVAC coil ends, tube manifolds, trimmed and threaded parts.

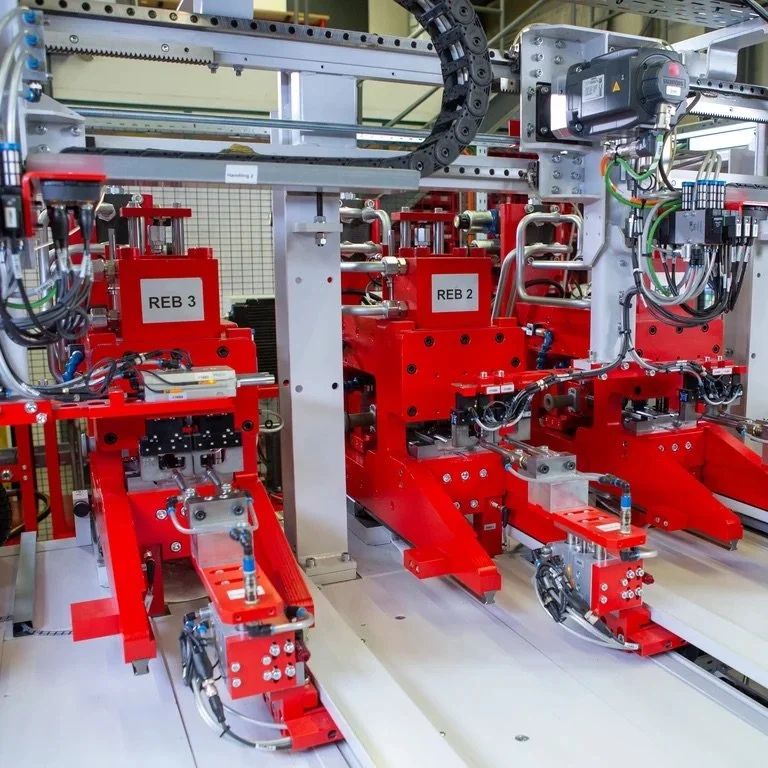

REB Axial Forming Machines

Compact, servo-driven units with up to 1,300 kN compression and multiple forming stages. They deliver precise, high-speed forming, even for challenging geometries and high-strength materials. Ideal for heavy-duty hydraulic tubes, aerospace lines, and structural components.

Combination Machines

These hybrid systems combine axial forming and rollforming in one sequence, streamlining multi-step profiles, eliminating extra setups, and enhancing precision on bent parts. Ideal for fuel rail systems, ORFS/hydraulic connections, and complex end geometries.

The power of tForm lies in its ability to work seamlessly with upstream and downstream automation from TRUMPF and transfluid. Whether you're forming ends before or after laser cutting or bending, tForm can be dropped into your production cell for a unified, hands-off process.

Integration That Elevates Quality and Efficiency

Here’s how it fits into the bigger picture:

Single-clamp operation: Secure the part once, complete the forming cycle without repositioning

Touch-panel controls: Store parameters and switch profiles in minutes—not hours

Plug-and-play with TRUMPF systems: Integrated forming, cutting, and bending with less human error

Optional ORFS ring feeders: Eliminate sealing failures by automating critical assembly steps

Smart sensors and diagnostics: Built for Industry 4.0 visibility and preventive maintenance

This results in better repeatability, shorter cycle times, and higher part quality without adding complexity to your workflow.

Precision End-Forming for These Industries

tForm systems are a natural fit for industries where tube-end integrity, surface finish, and geometric precision are non-negotiable:

Automotive & Aerospace: Hydraulic and fuel lines with tight tolerances

HVAC & Plumbing: Flaring, flanging, and mirror-finishing for clean seals

Appliances & Fixtures: Polished tube ends for visible or seal-critical assemblies

Agriculture & Construction: Durable, end-formed tubes for frames and fluid lines

Medical (with combo systems): Smooth, burr-free ends in bent stainless tubing

Why Maintecx Is The Right Partner

Maintecx is your exclusive TRUMPF dealer in the Upper Midwest and Southeast, and your integration partner for transfluid forming solutions. We deliver:

Engineering expertise to design your full automation cell

On-site implementation and operator training

Ongoing support with no vendor handoffs

Whether you’re retrofitting one step or building a full smart factory system, we help you finish with precision.

Finish With Precision

Start building your integrated cell with transfluid tForm and TRUMPF systems. Contact us today to get started.