On-Site Nitrogen Generation vs. Liquid Supply: The True Cost of Laser Cutting Gas

In modern fabrication, the laser cutter is the heart of the shop. But the actual operating cost extends far beyond the machine's initial price tag. For high-speed, clean laser cutting, especially with stainless steel and aluminum, nitrogen gas for laser cutting is a critical consumable. For most job shops, the biggest question is how to source it: liquid nitrogen (LIN) delivered by a supplier or an on-site nitrogen generation via an MSS Nitrogen Generator?

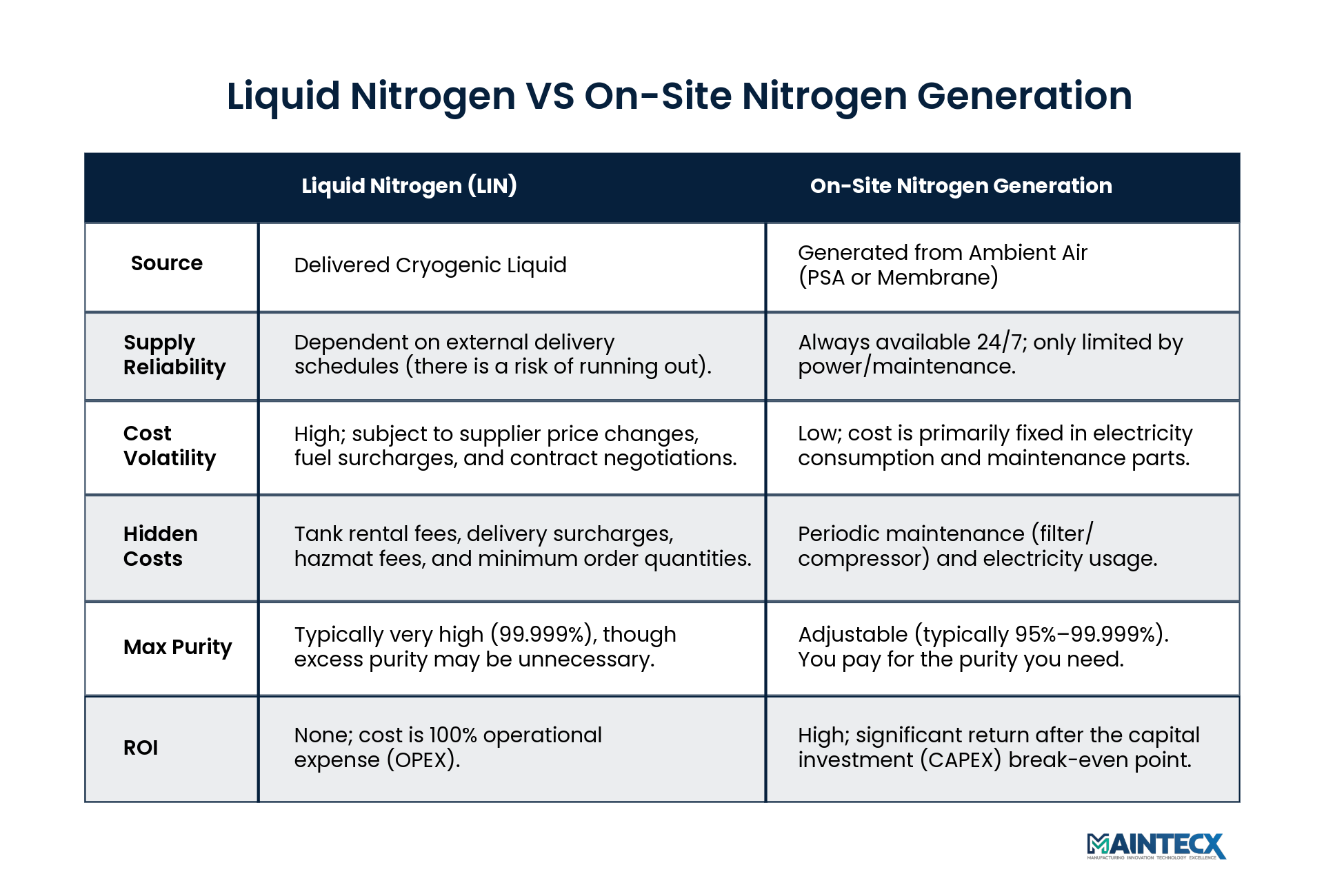

The difference between "buying" and "generating" is far more complex than a simple price-per-unit. It involves hidden costs, supply chain risks, and long-term control over your production quality and uptime.

In this blog, we’ll provide a direct, side-by-side comparison to help you determine which method offers the best long-term ROI for your operation.

Side-by-Side Comparison: Liquid Nitrogen vs. On-Site Generation

Deep Dive: Cost, ROI, and Hidden Fees

The initial focus on cost per cubic foot (liquid vs generated) often masks the true financial picture.

Cost Per Cubic Foot: The Deceptive Metric

When comparing the sticker price, LIN can initially appear competitive. However, this figure rarely includes the true expenses:

Liquid Nitrogen: The actual price per cubic foot of usable gas is inflated by vaporization loss, tank venting, and the numerous fees attached to the bulk contract. Your shop is paying for the gas, the delivery truck's fuel, and the cost of maintaining the supplier's cryogenic tanks.

On-Site Generation: After the initial capital investment, the cost per cubic foot is primarily determined by electricity consumption and periodic filter replacement. For high-volume users, this cost often settles at a fraction (sometimes 50–70% less) of the total liquid cost over time.

Hidden Costs That Sink LIN Budgets

The most significant drain on a liquid supply budget comes from non-gas-related charges:

Tank Rentals: Monthly fees for the bulk tank and associated vaporization equipment can add thousands annually.

Delivery Fees and Surcharges: Fuel surcharges, hazmat fees, and mandatory minimum delivery costs add unpredictable expense.

Price Volatility: LIN contracts are subject to market fluctuations. When demand is high or supply chain issues arise, your costs rise, sometimes without negotiation.

With an on-site system, these costs are eliminated. The only variable is your utility bill.

ROI: Turning OPEX into CAPEX with TRUMPF

Liquid nitrogen is a perpetual operational expense (OPEX) with no return on investment. On-site generation is a capital expense (CAPEX) that drives a clear ROI. For shops running high-power fiber lasers, the high gas consumption at high speeds makes the ROI case immediate. Most high-volume fabrication shops reach their break-even point (where the monthly savings from generating their own gas exceed the financing costs of the generator) within 24 to 48 months.

Furthermore, pairing your on-site generator with TRUMPF’s optional Highspeed Eco cutting feature can dramatically reduce nitrogen consumption by up to 70%. This combination maximizes your savings and extends the life of your generator's internal components, achieving the lowest possible total cost of ownership (TCO).

Uptime, Reliability, and Production Control

The largest non-financial risk to laser cutting is unexpected downtime.

Running Out vs. Always On-Site

Liquid Supply: Your entire production is hostage to a delivery schedule. If a delivery is delayed due to weather, logistics, or a supplier error, your laser cutter stops. Running out of gas means hours or even days of lost production.

On-Site Generation: The system uses a continuous supply of air and is integrated directly into your facility's power and air lines. As long as you have power, your nitrogen supply is continuous. This near 100% uptime reliability is invaluable for shops with tight deadlines.

Purity and Stability for Oxide-Free Fusion Cutting

For cutting thick stainless steel and aluminum, the quality of your nitrogen gas for laser cutting directly impacts the final part. TRUMPF uses nitrogen for fusion cutting to achieve oxide-free edges that require minimal secondary finishing.

Pressure Stability: High-pressure inert gas is critical for cleanly blowing molten metal from the kerf. An on-site system provides stable, continuous pressure, preventing the fluctuations often seen with a liquid supply and helping to maintain cut quality.

TRUMPF Smart Features: The generator ensures the consistency required for advanced TRUMPF functions, such as AdjustLine, which automatically optimizes cutting parameters for material inconsistencies. When your gas supply is unstable, these smart features cannot perform to their highest potential.

Connected Production: In a smart factory running Oseon software, every unplanned machine stop caused by an empty nitrogen tank is immediately recorded as lost productivity. On-site generation is a simple investment that ensures the reliability required for a fully connected, automated production environment.

Conclusion: Making the Strategic Decision

For small job shops with intermittent, low-volume nitrogen needs, the low initial investment of liquid nitrogen may still be justifiable.

However, for any fabrication facility running one or more laser cutters daily, on-site nitrogen generation is the strategic choice. It is an investment that provides greater cost control, superior reliability, and a predictable, substantial ROI within just a few years. It moves your operation from relying on external, volatile suppliers to complete self-sufficiency.

Ready to integrate a self-sufficient gas supply with a high-performance TRUMPF laser? Explore our full line of 2D laser cutting machines and automation solutions.