Automated Tube Handling with transfluid tMotion & TRUMPF

The biggest delays in tube fabrication often happen between machines, not at them. Manual handoffs slow you down, reduce consistency, and make automation harder.

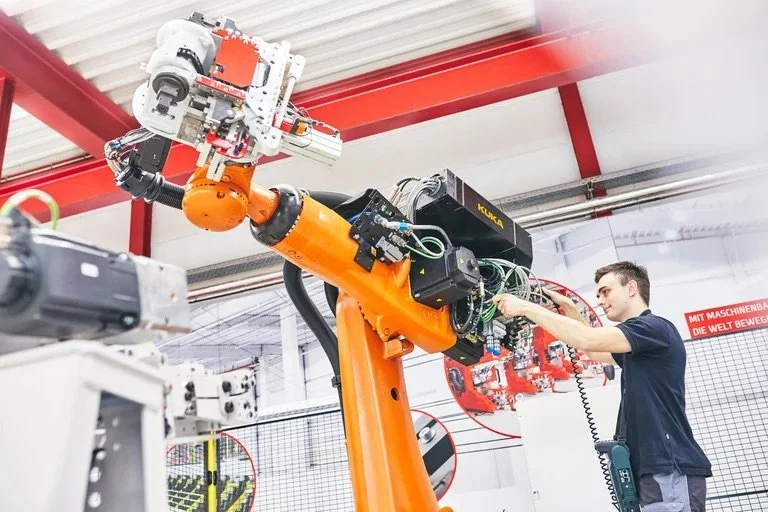

transfluid’s tMotion systems close that gap, automating part transfer, alignment, and staging between TRUMPF laser cutting and bending machines. And with Maintecx as your integration partner, you get one connected system built to move smarter, faster, and hands-free.

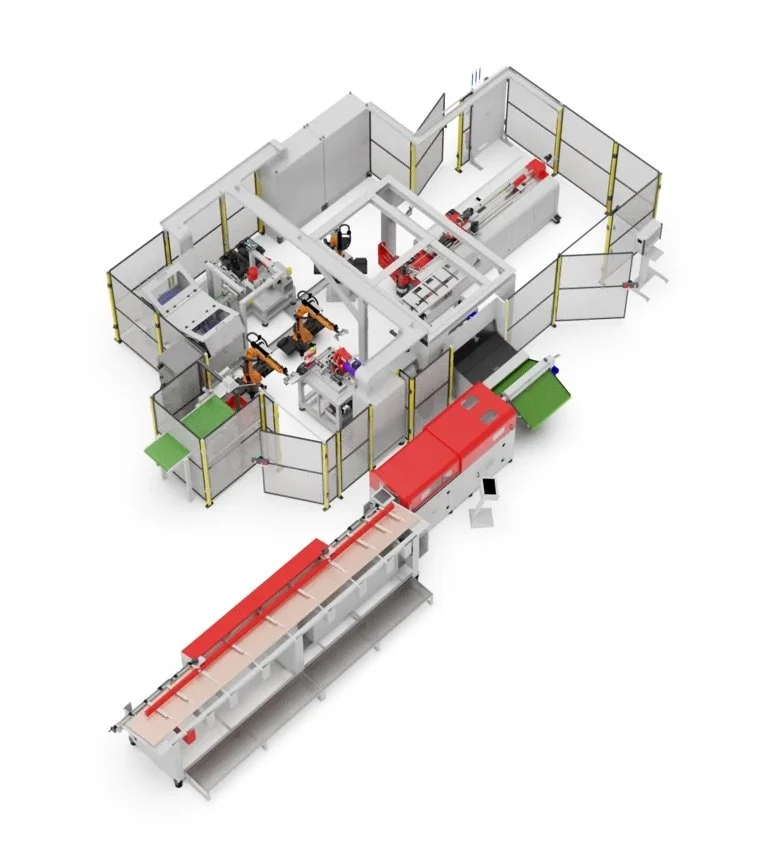

The transfluid tMotion platform enables modular automation that optimizes material flow across your tube production process. Key capabilities include:

Designing production cells tailored to your workflow

Integrating loading, alignment, and part marking systems

Incorporating optical quality checks and hole punching seamlessly

Enabling transfer lines that minimize cycle time and manual intervention

Whether in small setups or large-scale automation cells, this system streamlines transitions, increases throughput, and reduces handling errors.

Complete Tube Production Starts with

Seamless Motion

What Is transfluid tMotion?

transfluid tMotion is a highly modular automation framework designed to orchestrate the flow of tubes between cutting, bending, and finishing machines.

Key Features:

Custom-configured production cells tailored to your plant layout

Plug-and-produce readiness, supporting batch variability without delays

Seamless integration of loading/unloading systems, punching, camera-based inspection, and marking tools

Industry 4.0 compatibility, with data interfaces for diagnostics and performance monitoring

Fast cycle support, driven by fully automated handling for higher efficiency

How tMotion + TRUMPF Create a Unified Workflow

Enhance your tubing workflow with a turnkey automation flow:

Laser Cutting & Labeling: TRUMPF laser cutters precisely cut and label parts for traceability.

Automated Tube Transfer: tMotion systems manage loading and align components between machine steps.

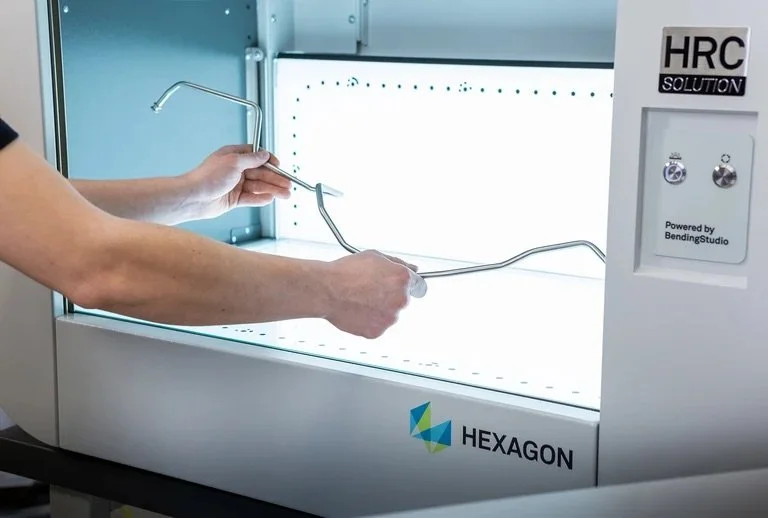

Inspection & Handling: Integrated cameras and sensors verify tube orientation and quality.

Processing & Finishing: Processed parts move to bending or punching systems, with optimized accuracy.

Efficient Throughput: Automated transfer lines and conveyors reduce manual handling and accelerate production.

The entire workflow is centrally controlled, enabling smarter throughput planning, part tracking, and highly repeatable performance across all stages.

Automation, Flexibility & Scalability

transfluid tMotion systems offer advantages that streamline operations and future-proof your shop:

Highly modular architecture, so automation grows with your needs

Flexible batch processing, from single-piece runs to large-volume jobs

Enhanced traceability with integrated marking and inspection systems

Effortless integration, thanks to customizable conveyor and robotic options

Reduced labor, faster throughput, and tighter quality control—all while keeping processes lean

Industries Optimized with tMotion + TRUMPF

This system is ideal for sectors that demand precision, throughput, and repeatability:

HVAC & Plumbing: Automated tube bends and fittings

Automotive: Frame components, exhaust, fuel systems

Aerospace: Hydraulic lines and structural tubing

Construction & Infrastructure: Fabricated assemblies for railings and support

Appliances & Fixtures: High-volume, precision tube components

Why Partner with Maintecx?

Maintecx is uniquely positioned to deliver full system value:

Exclusive TRUMPF dealer and certified transfluid integration partner

Turnkey automation solutions are analyzed, planned, and delivered by one team

End-to-end support from configuration through training and maintenance

A unified point of contact with no juggling between vendors

When you're ready to automate the “in-between” steps and produce more, faster, Maintecx helps you do it right.

Bring Motion to Your Tube Workflow

If you’re ready to streamline tube handling and eliminate production bottlenecks, we’re here to help. Let’s build a smarter, faster system together.