TruLaser Cell 7040

Meet the TRUMPF TruLaser Cell 7040, the most versatile 3D laser system in TRUMPF’s lineup. With its modular design and high-speed performance, this system adapts to your production needs, whether you’re forming automotive panels, laser welding fan components, or building up features with laser metal deposition (LMD).

Designed for flexibility, built for durability, and loaded with intelligent features, the TruLaser Cell 7040 makes advanced laser processing scalable and future-ready.

What is the TruLaser Cell 7040?

The TruLaser Cell 7040 is a modular 3D laser processing machine capable of laser cutting, laser welding, and LMD. You can perform all three operations on a single machine using one fiber optic cable (2-in-1 LLK). That means fewer setups, faster changeovers, and unmatched production flexibility.

Whether you’re cutting galvanized steel, welding pump couplings, or performing LMD for part repair, this machine delivers precise, repeatable results, even on large and complex parts.

Key Features and Capabilities

3-in-1 Processing: Cut, weld, and deposit material all in one machine. No need to switch stations or re-fixture parts.

Modular Design: Configure your work envelope and motion system to match your workflow. Choose your Y and Z-axis ranges, integrate rotary tables, and add stations as needed.

Smart Safety and Performance Tools: The X-Blast nozzle allows longer working distances, improving stability and reducing collisions. A magnetic coupling prevents costly damage during impact, snapping off safely and easily reattaching.

Fast, High-Dynamic Motion: With linear speeds of up to 100 m/min (3,937 in/min) and dual-station support, the 7040 keeps your line moving. Easily load, unload, or set up one station while the other runs.

Ergonomic Control & Remote Access: The movable control panel and MobileControl app let you operate the machine from inside or outside the enclosure.

Lower Cost of Ownership: Fewer changeovers, reduced tooling, and integrated quality monitoring drive down the machine-hour rate and increase uptime.

Lightweight GFRP Doors: Open and close ~35% faster for shorter door cycles and less waiting between jobs.

Two-Station Operation Options: Includes a rotary table (4-second changeover), movable loading tables, and a partition wall for parallel load/unload during production.

Applications Across Industries

Automotive: Deep-drawn body panels, battery enclosures, galvanized steel parts, hot-formed components

Aerospace: Fan wheels, engine parts, high-strength structural elements

Energy & Industrial: Pump couplings, large enclosures, pressure vessels

Repair & Rework: Additive build-up via LMD on worn or damaged components

Smart Technologies That Set It Apart

The TruLaser Cell 7040 includes or supports a range of TRUMPF smart modules designed to improve quality, productivity, and ease of use:

BrightLine Weld: Spatter-free laser welding with optimal seam appearance

ObserveLine (Comfort/Professional): Non-contact part inspection and cut verification

Smart Optics Setup: Fast, repeatable setup of cutting and welding optics

FocusLine: Automatic laser focus adjustment based on material and thickness

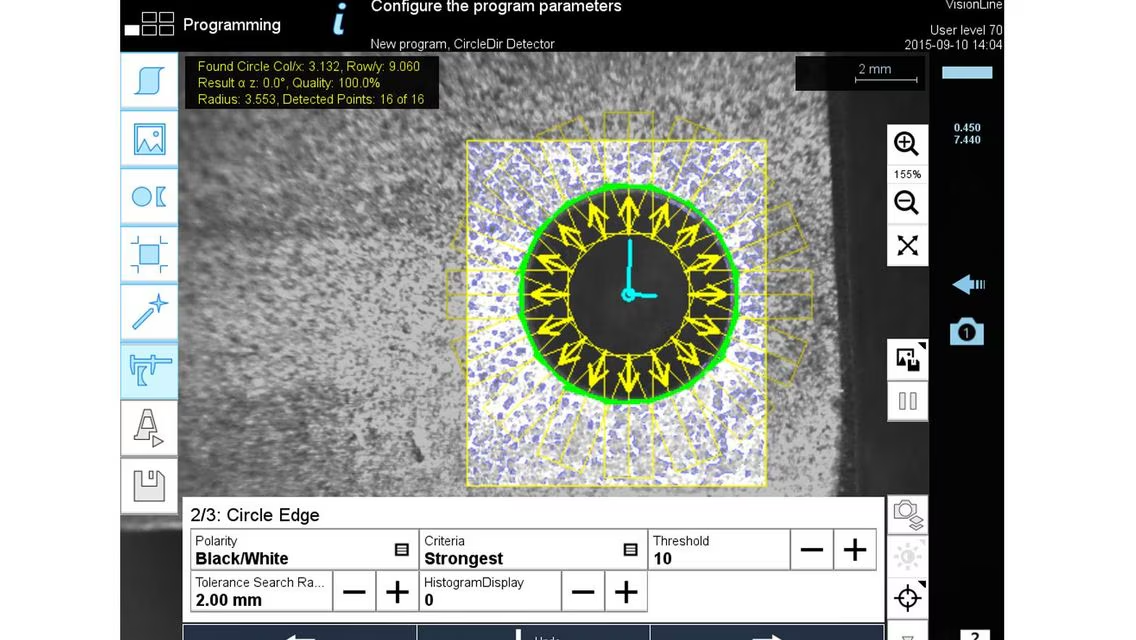

VisionLine: Camera-based seam detection for pinpoint accuracy

FastLine Cell: Reduce piercing times by up to 40% with intelligent on-the-fly piercing technology.

OPC/UA Connectivity: Enables integration into digital factory networks (Industry 4.0 ready)

TruLaser Cell 3000 Technical Data

Axis Travel Range

X Axis Travel

31.50 in (800 mm)

Y Axis Travel

59.06 or 78.74 in (1,500 / 2,000 mm)

Z Axis Travel

29.53 or 39.37 in (750 / 1,000 mm)

B Axis Travel

±135°

C Axis Travel

Unlimited rotation (n × 360°)

Dynamic Cutting Optics Travel

±0.35 in (±9 mm)

Maximum Axis Speeds

Max Speed X

3,937 in/min (100 m/min)

Max Speed Y

3,937 in/min (100 m/min)

Max Speed Z

3,937 in/min (100 m/min)

Max Simultaneous Axis Speed

6,811 in/min (173 m/min)

B Axis Max Speed

90 RPM (90 1/min)

C Axis Max Speed

90 RPM (90 1/min)

Maximum Axis Accelerations

Max Acceleration X

29.53 ft/s² (9 m/s²)

Max Acceleration Y

32.81 ft/s² (10 m/s²)

Max Acceleration Z

32.81 ft/s² (10 m/s²)

B Axis Acceleration

40,738 °/s² (200 rad/s²)

C Axis Acceleration

20,369 °/s² (100 rad/s²)

Dynamic Optics Acceleration

131.23 ft/s² (40 m/s²)

Positioning Accuracy

Linear Axes (X, Y, Z)

±0.00315 in (±0.08 mm)

Rotary Axis (B)

±0.015°

Laser

Max Laser Power

3,000 – 6,000 W

Available Lasers

TruDisk

Work In Tandem With

Options & Upgrades

Teach Panel & Touchscreen: Easy on-machine programming and adjustment

MobileControl App: Monitor and control the machine remotely

Rotary Tables & Sliding Worktables: Speed up part changeovers and fixture swaps

OPC/UA Protocol: Integrates with your MES or smart factory system

TruTops Cell & TruTops Boost:

Offline programming, simulation, and collision detection

Request a Quote from Maintecx

When you're ready for a production system that can cut, weld, and deposit metal all in one footprint, the TruLaser Cell 7040 delivers. Its modular design, intelligent features, and TRUMPF build quality make it a smart investment for high-mix, high-complexity manufacturing.