Automation Machines: Modular & Linear Fabrication Solutions

Automation machines are the backbone of a modern, cost-effective production floor. By automating the repetitive tasks of loading, unloading, and sorting, your team can move away from manual material handling and focus on high-value programming and machine management.

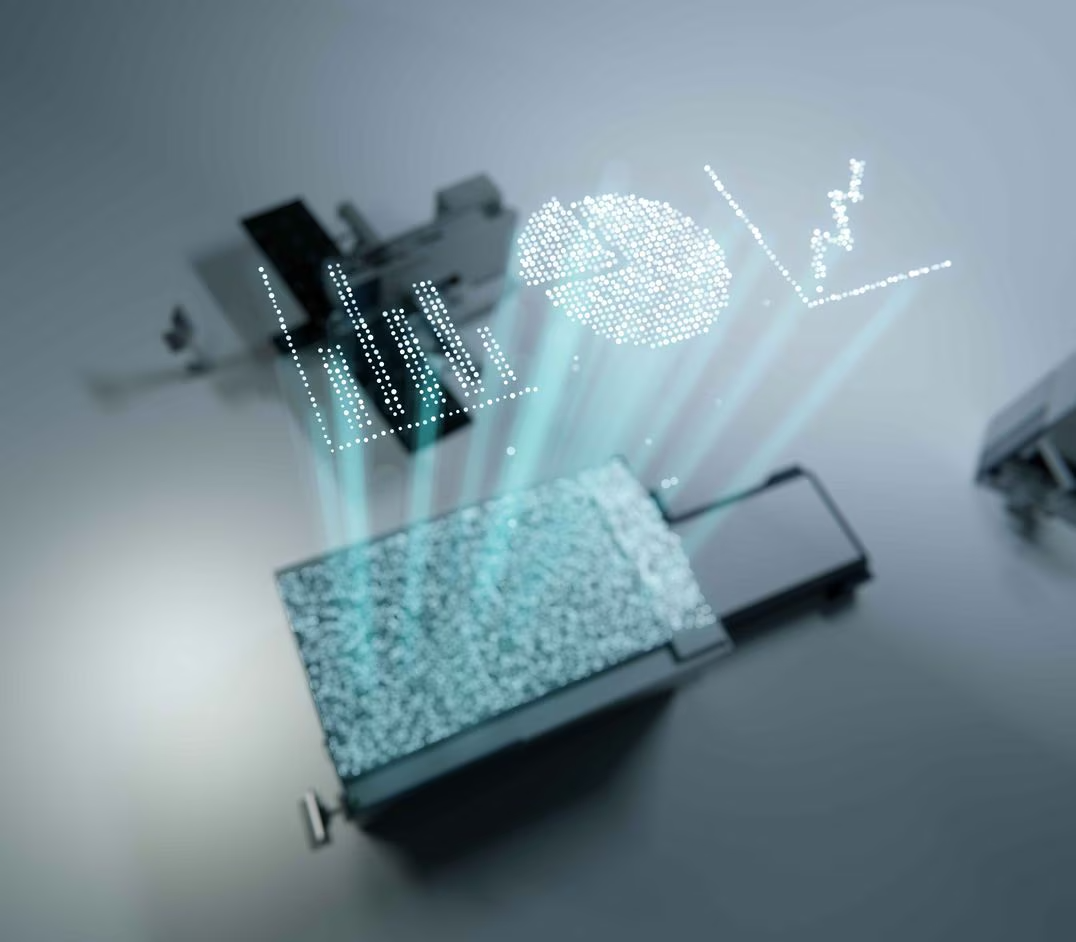

We specialize in laser automation and modular automation solutions that scale with your success. Whether you are looking for a standalone loading unit or a fully networked linear automation system connected to a storage warehouse, our TRUMPF-powered solutions are designed to make your factory "Smart." Through TruConnect, we enable a transparent, efficient production flow that guarantees reliability for your customers and higher margins for your business.

TRUMPF Automation Systems: From Loading to Sorting

TRUMPF offers a comprehensive ecosystem of automation components. These systems are highly modular, allowing you to start with basic loading automation and expand as your throughput increases.

The LoadMaster is the universal loading unit for 2D laser machines. It uses a vacuum suction device to reliably move raw sheets from the loading station to the pallet changer and is a perfect entry point for shops looking to increase productivity at a lower cost-per-part

The LiftMaster is a versatile gantry solution that handles loading, unloading, and sorting. It offers numerous setup options, including LiftMaster Linear for multi-machine connections and LiftMaster Store for direct warehouse integration, making it the gold standard for flexible sheet metal logistics.

For shops with limited floor space, the LiftMaster Compact delivers high-speed loading and unloading in a minimal footprint. With cycle times of 90 seconds, it is the fastest solution for high-volume 2D laser processing.

Achieve touchless production by connecting your 2D laser cutting machine and press brake into a single autonomous flow. By integrating cutting and bending via a storage system, you slash throughput times and eliminate the risk of part damage during manual transport.

Specifically designed for laser tube cutting, the LoadMaster Tube automates the material supply from a bundle space that can hold up to four tons of unprocessed material. This ensures your tube laser runs continuously with zero setup delays.

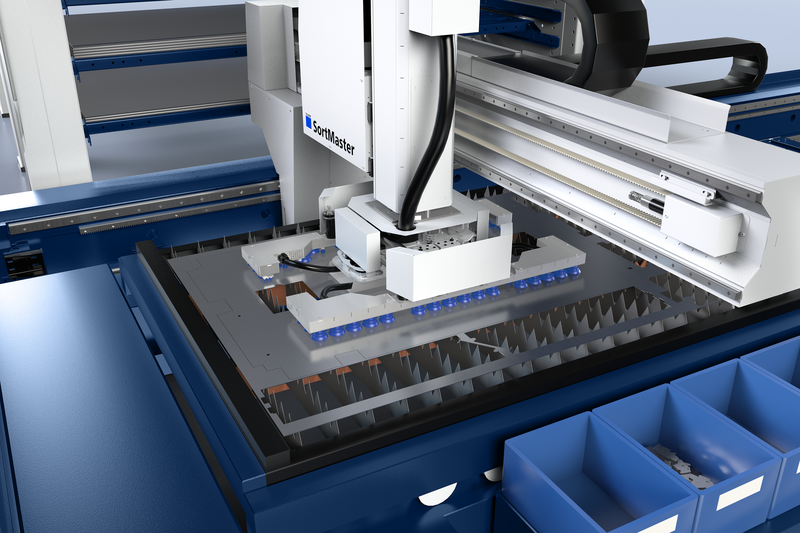

The SortMaster removes, sorts, and stacks finished parts from the scrap skeleton. Utilizing optical image recognition and AI (SortMaster Vision), it removes the need for manual sorting and time-consuming programming.

Stop wasting time on manual tool setups. The ToolMaster Bend changes tools on your TruBend press brake in seconds, protecting them from damage and keeping the operator focused on bending rather than searching for tooling.

GripMaster automates scrap removal for punching and punch-laser machines. Picking up the scrap skeleton and depositing it in a container creates a cleaner, safer work environment and allows for unattended night shifts.

FAQs About TRUMPF Automation

-

Flex automation refers to standalone robotic cells or modules that can be reconfigured for different tasks. Linear automation typically involves a gantry or rail system (such as the LiftMaster Linear) that connects multiple machines to a central storage system, enabling continuous material flow across the entire shop.

-

Most TRUMPF automation components are modular and can be retrofitted to existing machines. This allows you to increase automation as your production volume and budget allow.

-

Automation doesn't replace skilled workers. By automating "dull, dirty, and dangerous" tasks like lifting heavy sheets or sorting scrap, your skilled operators can focus on machine optimization, quality control, and advanced programming.

Learn More About TRUMPF Automation

Upgrade Your Operation with Automation

We’ll help you design and configure the best automation flow for your shop and applications. Contact us to request a quote or explore your options with a Maintecx Rep.