Slat Cleaners 101: How to Get Cleaner Laser Cuts & Longer Slat Life

Your laser cutting machine is only as good as the surface it rests on. While much focus is placed on the laser source and optics, the state of your support slats plays a massive role in the final quality of your parts.

If your slats are coated in heavy slag and dross, you’re actively compromising your throughput and increasing your cost-per-part. Here is everything you need to know about why a slat cleaner is an essential tool for any modern fabrication shop.

What Your Dirty Slats Are Actually Costing You

When slag accumulates on the slats, it creates uneven, mountainous surfaces. This leads to three major issues:

Back-Reflections and Welding: With fiber lasers, in particular, the beam can reflect off slag buildup and strike the underside of your workpiece. This causes "slugging" or welding the part to the slag, resulting in a poor edge finish and difficult part removal.

Part Tipping: Uneven slats mean your parts don't sit flat. This can cause the laser head to crash into a tipped part, leading to expensive downtime and potential lens damage.

Contamination: Slag buildup from previous mild steel jobs can contaminate stainless steel or aluminum workpieces, leading to rust or aesthetic defects that cause part rejections.

Why Use a Dedicated Laser Slat Cleaner?

Many shops still rely on manual hammers or homemade scraping tools. These methods are not only slow and physically exhausting but also prone to damaging the slats, shortening their lifespan.

A professional laser slat cleaner like the TRUMPF TruTool series provides:

Speed: Clean an entire table in minutes, not hours.

One-Person Operation: Designed for ergonomic use, allowing a single operator to clean slats without removing them from the machine.

Consistency: The cleaning tools chip away the slag evenly, maintaining the flat profile of the slats and extending their life by up to 3–4x compared to manual scraping.

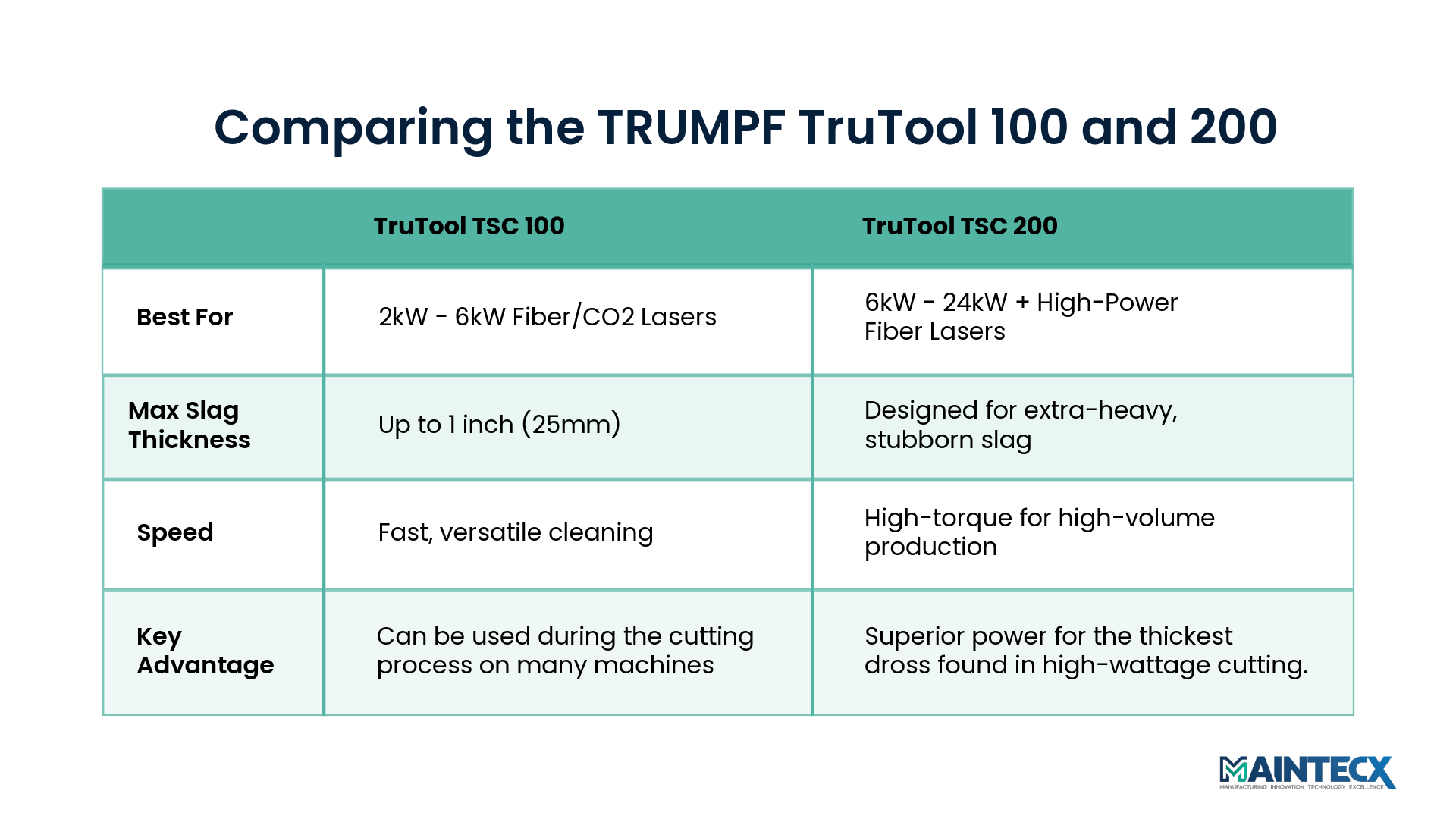

TRUMPF Technology Highlight: TSC 100 vs. TSC 200

Maintecx offers two primary solutions for automated slat cleaning. While both are built with TRUMPF precision, they are designed for different operational intensities.

The TSC 100 is the industry standard for most job shops. It is highly adaptable and can even be used while the machine is running (on machines with a pallet changer), ensuring zero loss in production time.

The TSC 200 is engineered for the new generation of ultra-high-power fiber lasers. These 12kW to 24kW machines produce a denser, harder slag that requires additional torque and specialized cleaning tools, features found in the TSC 200.

Pro-Tips: How Often Should You Clean?

Cleaning frequency is not "one size fits all." It depends heavily on your material mix and laser power:

High-Power Fiber (12kW+): These machines generate slag rapidly. We recommend a quick pass with a slat cleaner every 1–2 days to prevent the dross from hardening into an unmanageable state.

Stainless Steel & Aluminum: If you frequently switch between materials, clean the slats before starting a high-quality stainless job to prevent carbon contamination from previous mild steel runs.

Copper Slats: If you use copper-tipped or full-copper slats, cleaning is even easier because slag does not bond as strongly to copper. However, regular cleaning is still required to maintain the table's height accuracy.

The Bottom Line: Clean Slats = Better ROI

A TRUMPF slat cleaner is one of the few power tools that pays for itself almost immediately. By reducing part tipping, improving edge quality, and extending the life of your slats, you protect your larger investment: your laser cutting machine.

Stop fighting with hammers and scrapers. Get a cleaner cut and a more reliable process with the right maintenance tools. Explore our available slat cleaners from TRUMPF.