TruLaser Cell 5030

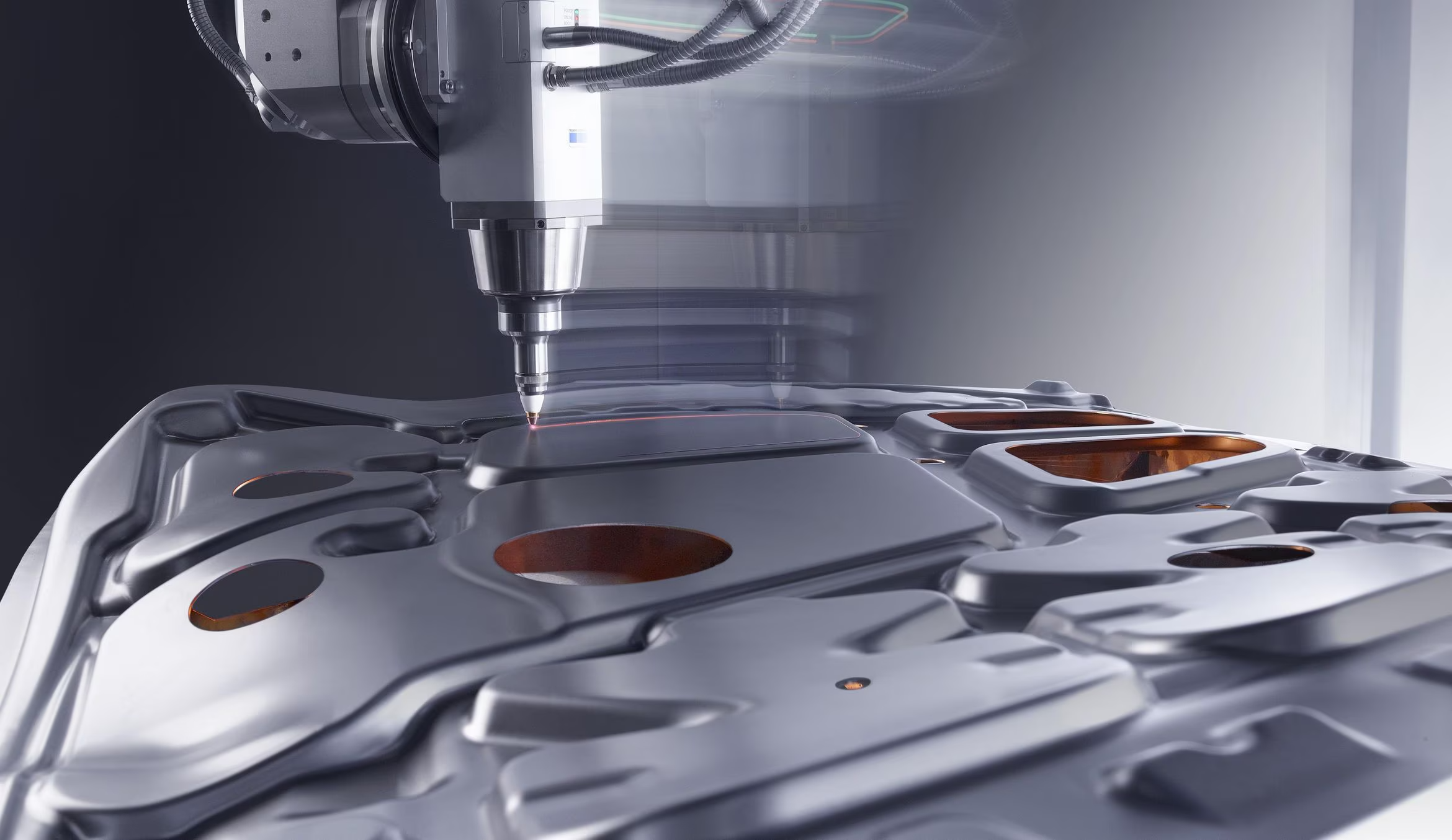

A compact and cost-effective solution to bring 3D laser cutting in-house is here. The TRUMPF TruLaser Cell 5030 is built for flexibility, precision, and speed. Designed for laser cutting complex 3D components, it’s an ideal choice for small to mid-sized batch production across industries like automotive, aerospace, and contract manufacturing.

With full 5-axis motion and a small footprint, this system delivers high-end performance without taking over your floor space.

What is the TruLaser Cell 5030?

The TruLaser Cell 5030 is a 3D laser cutting system that offers full multi-axis capability in a space-saving format. Whether you're cutting hydroformed parts, welded assemblies, or stamped components, this machine delivers precise, repeatable results even on complex geometries.

Built with efficiency in mind, the 5030 is optimized for quick job changes, reduced setup times, and outstanding part accessibility thanks to its ergonomic layout and large working area.

Key Features and Capabilities

Full 5-axis motion: Cut 3D parts, beveled edges, and complex contours with speed and accuracy.

Compact design: Small footprint, big capabilities, ideal for tight production floors.

Magnetic coupling system: Reduces downtime and damage from collisions.

X-Blast nozzle: Doubles the working distance, enhances stability, and improves cut quality.

Rapid job changeover: Accessible layout and intuitive controls simplify part swaps and setup.

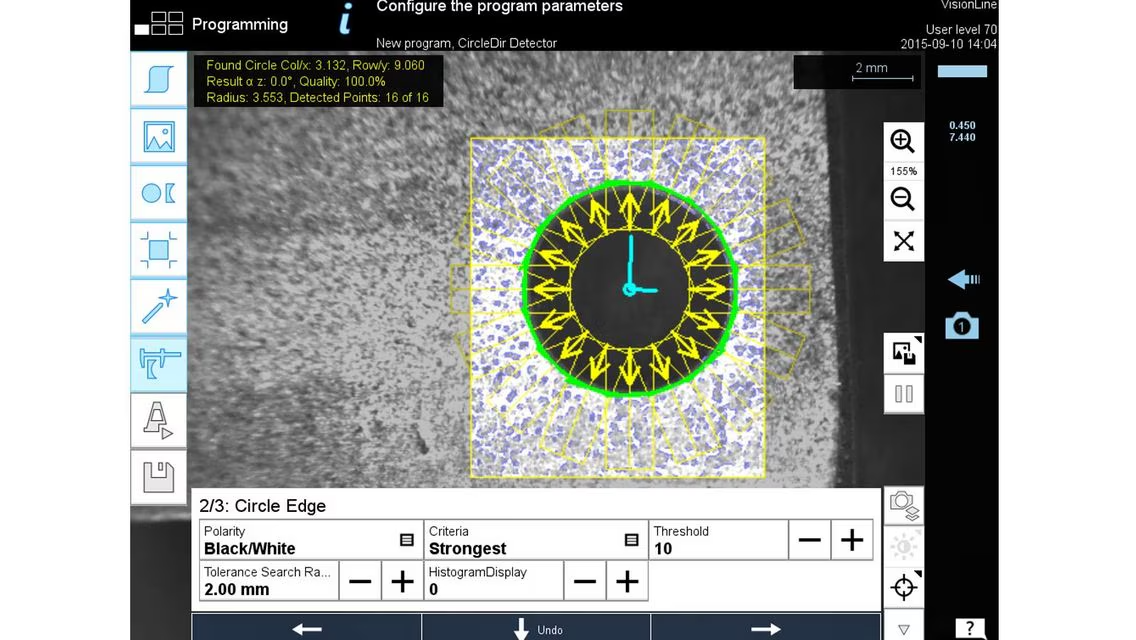

Teachbox + Touchscreen Interface: User-friendly programming for fast adjustments and efficient operation.

Lower operating costs: Compared to hybrid CO₂ systems, the 5030 delivers up to 300% higher performance and 20% lower machine-hour rates.

TRUMPF quality: Designed and built to the highest standards for laser cutting excellence.

Applications Across Industries

The TruLaser Cell 5030 is engineered to handle high-mix, high-precision applications across several industries:

Automotive: Ideal for body panels, hydroformed tubes, and structural parts.

Aerospace: Cut lightweight structural components with accuracy and repeatability.

General Fabrication: High-mix, low-volume 3D parts or prototype runs.

Contract Manufacturing: Flexible enough for low-volume or batch production of diverse 3D parts.

TruLaser Cell 3000 Technical Data

Axis Travel Range

X Axis Travel

118.11 in (3,000 mm)

Y Axis Travel

59.06 in (1,500 mm)

Z Axis Travel

27.56 in (700 mm)

Rotary Axes

B Axis

±135°

C Axis

360° continuous

Maximum Axis Accelerations

Linear Axes (X/Y/Z)

236.22 in/min (60 m/min)

Combined Axes

409.45 in/min (104 m/min)

B & C Axes Speed

60 RPM

Accelerations

Linear Axes

26.25 ft/s² (8 m/s²)

Combined Axes

45.28 ft/s² (13.8 m/s²)

B Axis Acceleration

40,738 °/s² (200 rad/s²)

C Axis Acceleration

20,369 °/s² (100 rad/s²)

Positioning Accuracy

Linear Axes

±0.00315 in (±0.08 mm)

Rotary Axis (B)

±0.015°

Laser Power Options

3–4 kW

Compatible Lasers

TruDisk, TruFiber

Work In Tandem With

Options & Upgrades

Rotary Axes & Clamping Systems: Handle tubes, welded assemblies, or asymmetric parts with rotary motion and flexible workholding.

Spatter-Free Welding (BrightLine Weld: Switch seamlessly from cutting to welding with smoother, cleaner weld seams using optional TRUMPF technology.

Automation Packages: Optional add-ons for robotic part loading, unloading, and handling to streamline production and reduce manual labor. Learn more about TRUMPF automation

Software & Programming Tools

Use TruTops Cell Basic for offline programming, collision checking, and automated path optimization. Easily adjust jobs on the machine with the Teachbox and touchscreen interface.

Request a Quote from Maintecx

The TruLaser Cell 5030 delivers flexibility, performance, and TRUMPF reliability in a compact package at a price point that makes it accessible for more shops than ever. Maintecx will help you select, configure, and support the right solution for your operation.