When’s the Last Time You Had a Manufacturing Process Audit?

Most shops are busy trying to hit deadlines, meet quotas, and keep machines running. But even if everything seems to be working, that doesn't mean you're operating at peak efficiency. In fact, small inefficiencies in your process can pile up into lost time, unnecessary scrap, overworked machines, and inconsistent quality, and most teams don’t realize it until the costs become too big to ignore.

That’s where a manufacturing process audit comes in, and why it might be time to schedule one on your calendar.

What Is a Manufacturing Process Audit?

A manufacturing process audit is a structured, hands-on evaluation of how your shop runs. We're not just talking about compliance checks or quality certifications. This is about walking your floor, observing your workflow, and identifying where you might be bleeding time or money.

Audits focus on how your operators, machines, software, and material handling all work together. This can include reviewing:

Machine settings and usage patterns

Operator workflows and skill gaps

Upstream and downstream process integration

Software utilization and digital interfaces

Maintenance routines and safety compliance

The goal is to spot bottlenecks, inefficiencies, outdated procedures and machines, and opportunities to improve.

Audits vs. Optimization: What’s the Difference?

Think of the audit as your diagnostic. It highlights what’s working, what’s not, and what’s being overlooked. Optimization is what happens after: fixing inefficiencies, retraining teams, reprogramming machines, or updating workflows.

What Gets Reviewed During a Process Audit?

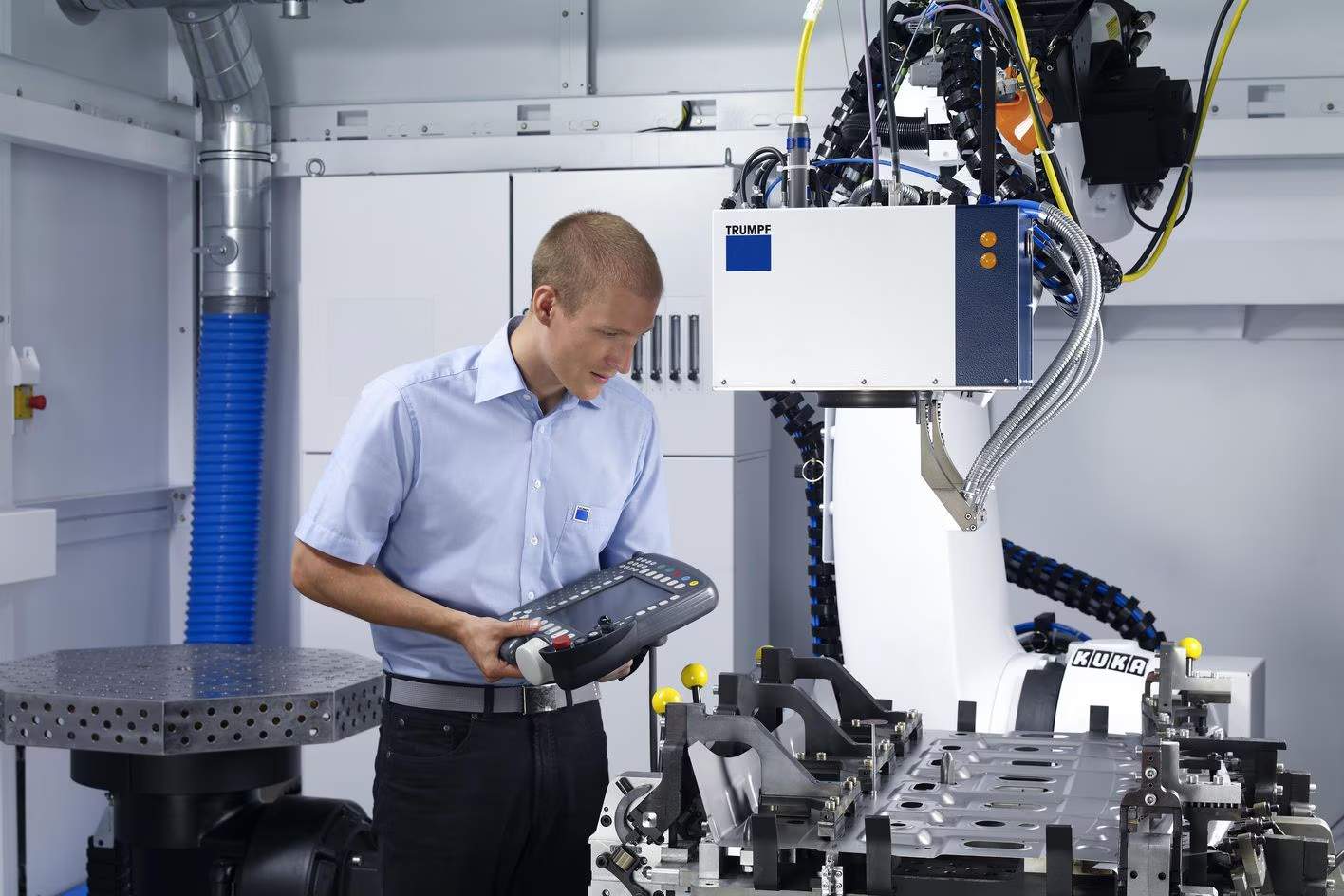

TRUMPF machines are incredibly powerful, but only if they're used to their full potential. If you're running manual setups, using outdated programs, or haven't reviewed your part flow in a while, you could be holding your shop back. A process audit should focus on six core areas:

Are You Getting Full Value from Your TRUMPF Machines?

Are you leveraging your TRUMPF’s smart sensors, automation modules, or software features like TruTops Boost? Our engineers look at what your machine can do and compare it to how it’s being used daily. Underutilized features often equal missed efficiency.

Cut Setup Time, Boost Part Flow

How does material travel through your facility, and how often does it wait? We observe the entire process, from raw sheet to finished part, and recommend ways to eliminate double handling, reduce staging delays, and keep machines fed efficiently.

Stop Wasting Time on Manual Programming

Software can make or break your process. We evaluate how your team is using TruTops, check for missed nesting and sequencing improvements, and review ERP or MRP integration. Even small changes in programming workflows can dramatically improve throughput.

Upgrade Habits Without Slowing Production

From clever workarounds to risky shortcuts, experienced operators often develop habits that cost more than they save. We work shoulder-to-shoulder with your team, spot inefficiencies, and provide live coaching tailored to your machines and parts.

Spot Hidden Problems Before They Cost You

That dull punch or worn-down sensor might be quietly sabotaging your quality. Our engineers flag subtle wear issues and help you create maintenance strategies to prevent unexpected downtime without over-servicing your machines.

More Than Checklists: Safety That Works

Safety isn’t just about OSHA compliance. We look for ergonomic problems, overlooked hazards, and missed opportunities to create safer workspaces. This protects your team and helps reduce liability.

Signs You’re Due for an Audit

Still unsure if it’s time? If any of these sound familiar, a process audit can help:

You’ve added new machines, but haven’t adjusted upstream processes.

Setup times have crept up over the past 6–12 months.

You’re seeing a rise in part rejections or scrap.

Work-in-progress (WIP) inventory is stacking up.

You’ve lost a key operator, and things feel less efficient.

Software updates were installed, but no one’s been trained on them.

Throughput hasn’t improved despite the use of better equipment.

What You Can Expect After an Audit

We don’t just hand you a list of suggestions and leave you to it. Our applications engineers provide detailed documentation, and then work with your team to:

Adjust machine programs for faster setups

Implement best practices for nesting, part sequencing, or fixturing

Recommend operator training or automation improvements

Fine-tune software usage and reduce manual steps

Offer strategies to reduce scrap and improve material yield

This hands-on approach leads to faster return on investment (ROI) on your TRUMPF equipment and helps your team run leaner, safer, and more confidently.

Why Choose Maintecx Application Engineering?

Our applications engineering team lives on the shop floor. They understand real-world production challenges and how to get more out of your TRUMPF machines, software, and people. You’re getting a partner who coaches your team, implements changes, and measures progress.

Whether you’re trying to scale production, reduce costs, or just understand why things feel slower than they used to, we’ll help you get clarity and control. We’ve helped hundreds of shops across the country:

Unlock underutilized automation tools

Cut 20% off the changeover times on the first visit

Solve persistent quality problems from wear or improper tooling

Align machine, material, and software to maximize throughput

Ready to Improve Your Production Setup?

If it’s been more than a year since someone took a hard look at your process, you’re probably overdue. Let our applications engineers help you find the blind spots, fix the inefficiencies, and get your TRUMPF machines running like they should. Explore Application Engineering Services to schedule a custom manufacturing process audit for your facility.